Mengxin Zheng will present a dynamic e-poster on 3D printed glass preforms for optical fibers with nonequilibrium cross-sections, from 11:30am to 1:00pm on May 13, 2020, in San Jose Convention Center, San Jose, California. CLEO 2020 will be held from May 10 to May 13, 2020. Mengxin conducts her research in collaboration with Camila Faccini de Lima and Veda Narayana Koraganji.

Techniques for the additive manufacturing of preforms for optical fiber applications have developed significantly in recent years, with major improvements in 3D printing of polymer preforms, which can be attributed to the bigger availability of high-quality commercially available printers for polymers. Beyond thermoplastics, glasses have significant scientific and engineering applications in optics, communications, and electronics[1]. Structured silica fibers could benefit multiple application areas, including optical-chemical detection, telecommunication and tight focusing of light. A 2-step process is generally used to fabricate these fibers: preform fabrication and the thermal draw of the preforms into a fiber[2]. The preform can be built using a variety of techniques such as metal-organic chemical vapor deposition, extrusion or 3D printing. The preform is then heated in a furnace and elongated into a fiber while preserving its cross-sectional arrangement.

Even though fibers are universally ubiquitous, the demand for optical fiber designs with complex cross-sectional geometries is difficult to meet with current fabrication methods. The preform fabrication, at this point, requires case-by-case treatment, and for each specific preform configuration, a separate technology must be developed and applied. Addressing this concern, we have therefore developed a method where glass fiber preforms are fabricated by Stereolytograpy-based 3D printing.

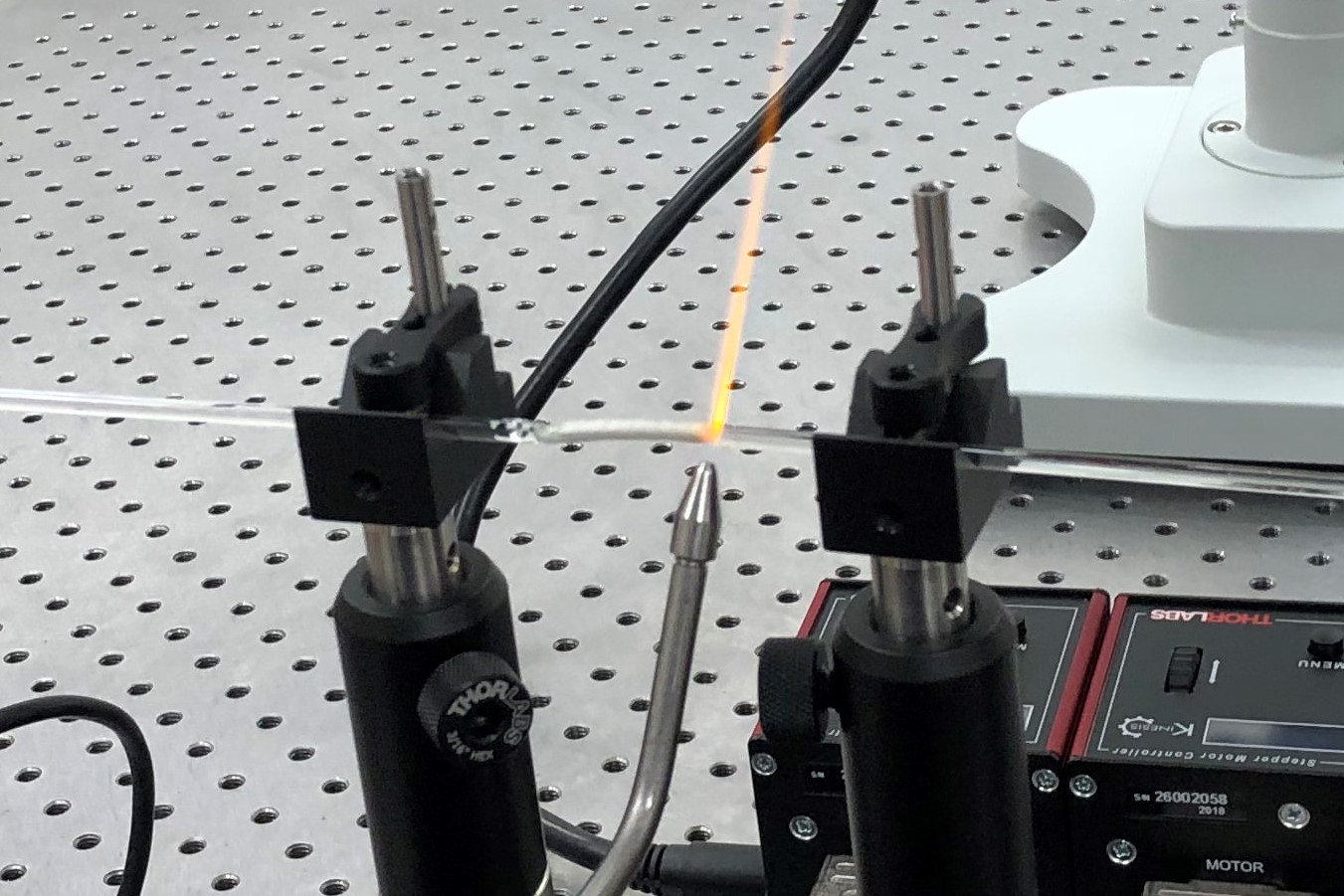

Our results, although focused on borosilicate glass as a proof of concept for the viability of our approach for 3D printing glass preforms, is easily translatable to fused silica and other glass compositions, thus providing good flexibility in the material choice. Furthermore, we demonstrate the ability to print preforms with non-equilibrium cross-sectional geometries, that are preserved after a fiber draw. We believe that minor improvements in the draw setup will enable the draw without torch-caused deformation, so that the preform cross-section can be retained. We demonstrate the viability of our approach for 3D printing glass preforms.

[1]Luo J, et al. “Additive manufacturing of glass for optical applications,” in Proc. SPIE9738, Laser 3D Manufacturing III, 97380Y (2016).

[2]Faccini de Lima, C., van der Elst, L. A., et al. “Towards Digital Manufacturing of Smart Multimaterial Fibers,” Nano. Res. Lett. 14, 209 (2019).