Major Instruments

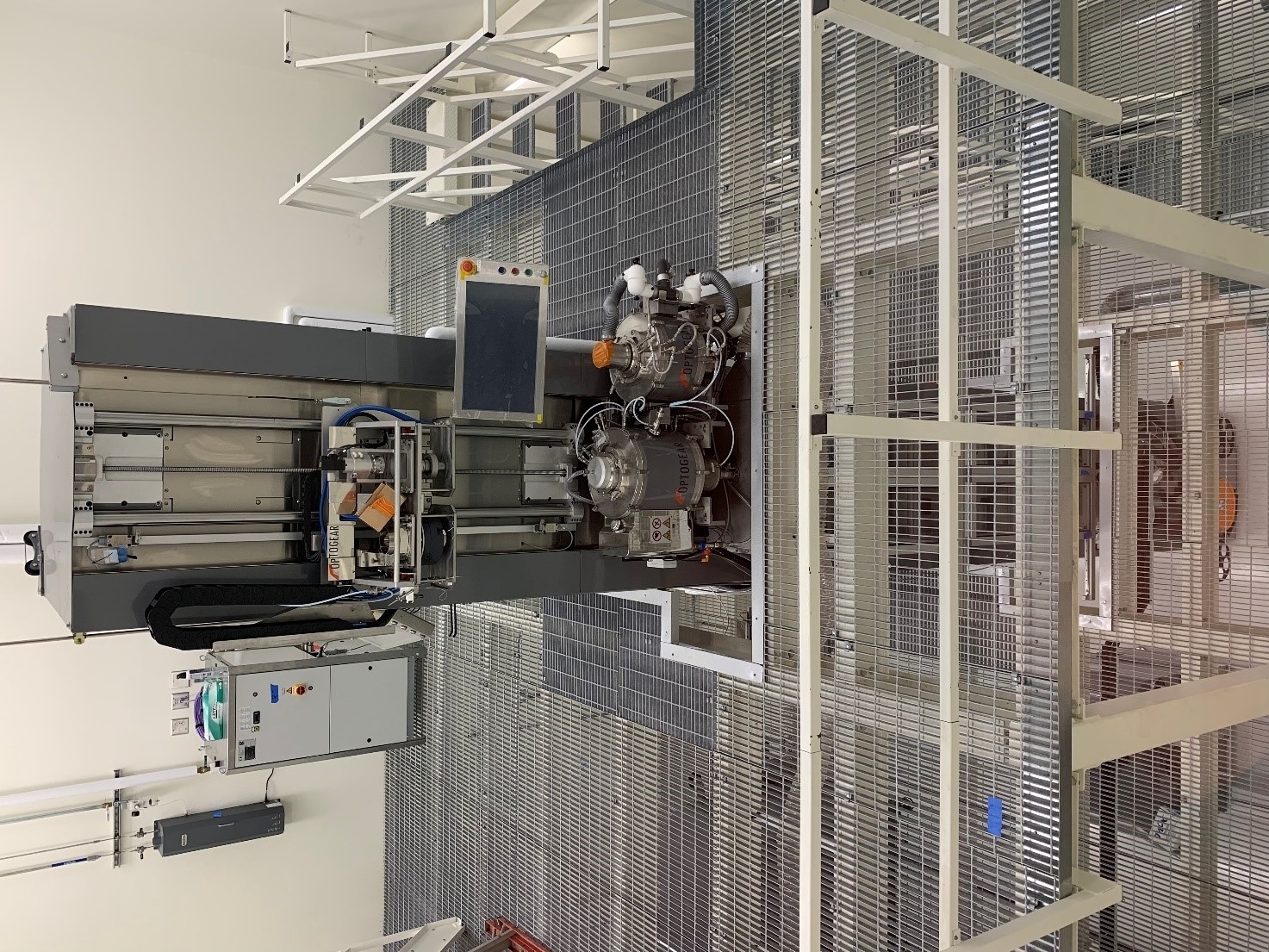

Featured below are selected key equipment of the FAMES Lab.Specialty Fiber Draw Tower (Optogear OG-510 D) – A 26-ft. high setup for thermal drawing of specialty fibers. Thermal drawing is a process commonly used in the fabrication of optical communication fibers. In this process, a glassy rod (preform) is fed into a furnace from the top, where it is heated to become a viscous liquid and is drawn into a fiber from the bottom of the furnace, similar to pulling taffy.

The draw tower at the FAMES Lab is a double-sided setup with two independent draw lines, equipped with three furnaces designed for fused silica, soft glasses, and polymers. Temperature range: room temperature to 2500°C (4532°F). The system accepts preforms up to 50 mm (1.97”) thick and produces high-quality fiber at a rate of up to 100 m/min (328 ft/min).

For detailed specifications and additional information, please refer to the catalog entry here. (access required)

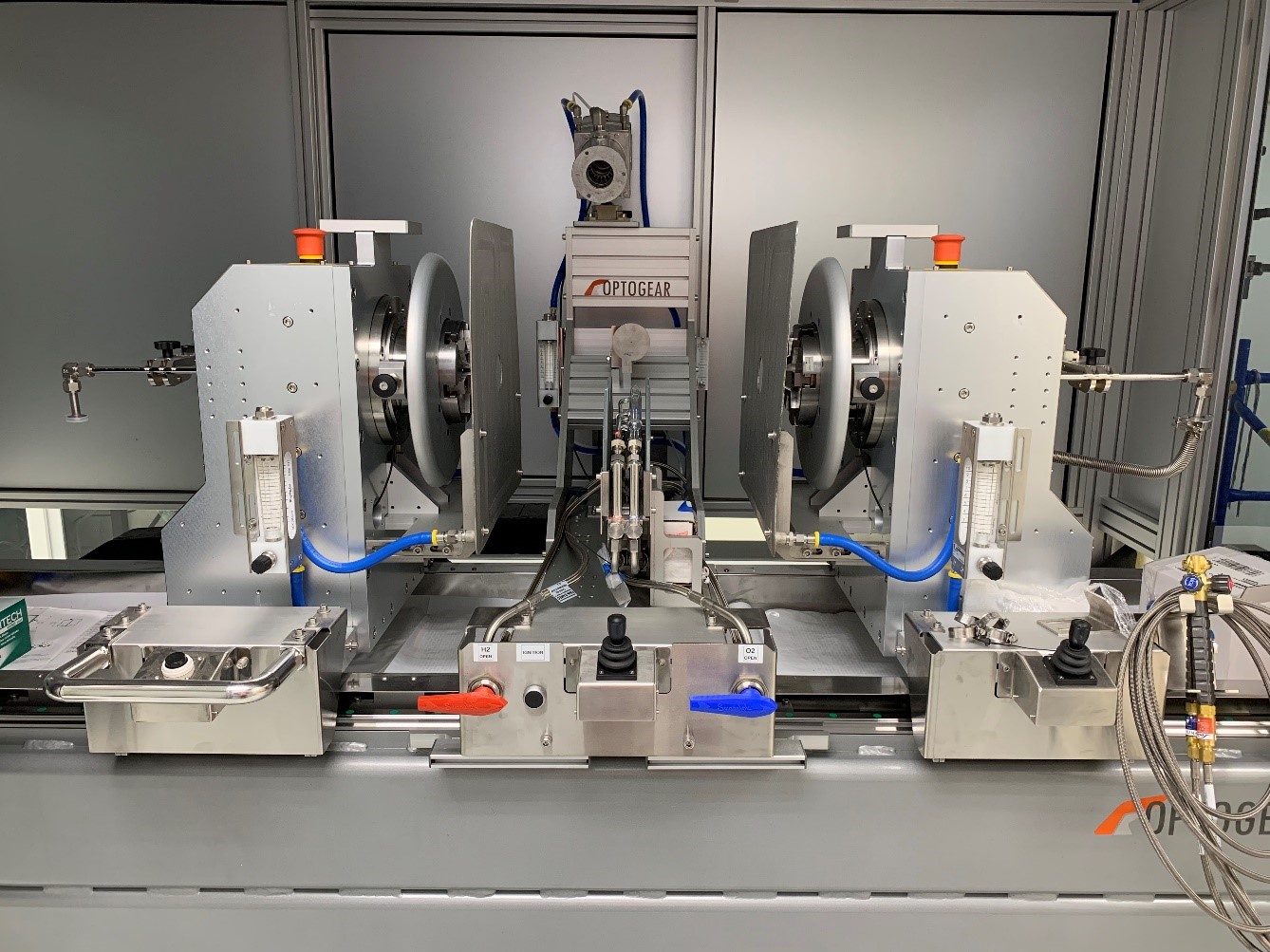

Glass Working Lathe (Optogear OG-440) – A setup for fabricating silica glass fiber preforms. This system is capable of scaling and collapsing glass tubes at a controllable rate, and sealing core materials within the preform under high vacuum (10⁻⁵ mbar) using hydrogen-oxygen burners and a turbo-pump vacuum system. Temperature range: 1000°C to 2500°C (1832°F to 4532°F), with a heat capacity of 35 to 40 kW (120,000 to 137,000 BTU/h).

For detailed specifications and additional information, please refer to the catalog entry here.

Spark Plasma Sintering (SPS) Hot Press (AGUS-PECS SS-250Rx) – In SPS, RF current is passed through a powder compact. Heat is generated mainly at the boundaries between powder grains due to increased impedance, allowing compacting the powder without melting the grains, in contrast to conventional hot pressing. This preserves the size- and structure-dependent properties of individual nanoparticles. Due to the very high heating/cooling rate (up to 1000 K/min), sintering of a sample takes only a few minutes. SPS is a preferred method for preparing ceramics based on nanoparticles with enhanced magnetic, magnetoelectric, piezoelectric, thermoelectric, optical, or biomedical properties. It allows sintering nanotubes/nanowires without destroying their structure and sintering materials with dissimilar melting points into the same compact.

The FAMES Lab SPS system is capable of handling sintering loads ranging from 2 to 250 kN (450 to 56,202 lbf) and operates across a broad temperature range, from room temperature to 2500 °C (4532 °F). It supports a maximum sample height of 30 mm and varying maximum sample diameters, depending on the processing temperature. For high-temperature materials (up to 2500 °C), the maximum diameter is 30 mm (1.18”); for semiconductors (up to 1500 °C), it is 60 mm (2.36”); for borosilicates (up to 700 °C), the diameter increases to 100 mm (3.94”); and for polymers (up to 300 °C), the maximum diameter remains 100 mm (3.94”).

For detailed specifications and additional information, please refer to the catalog entry here. (access required)

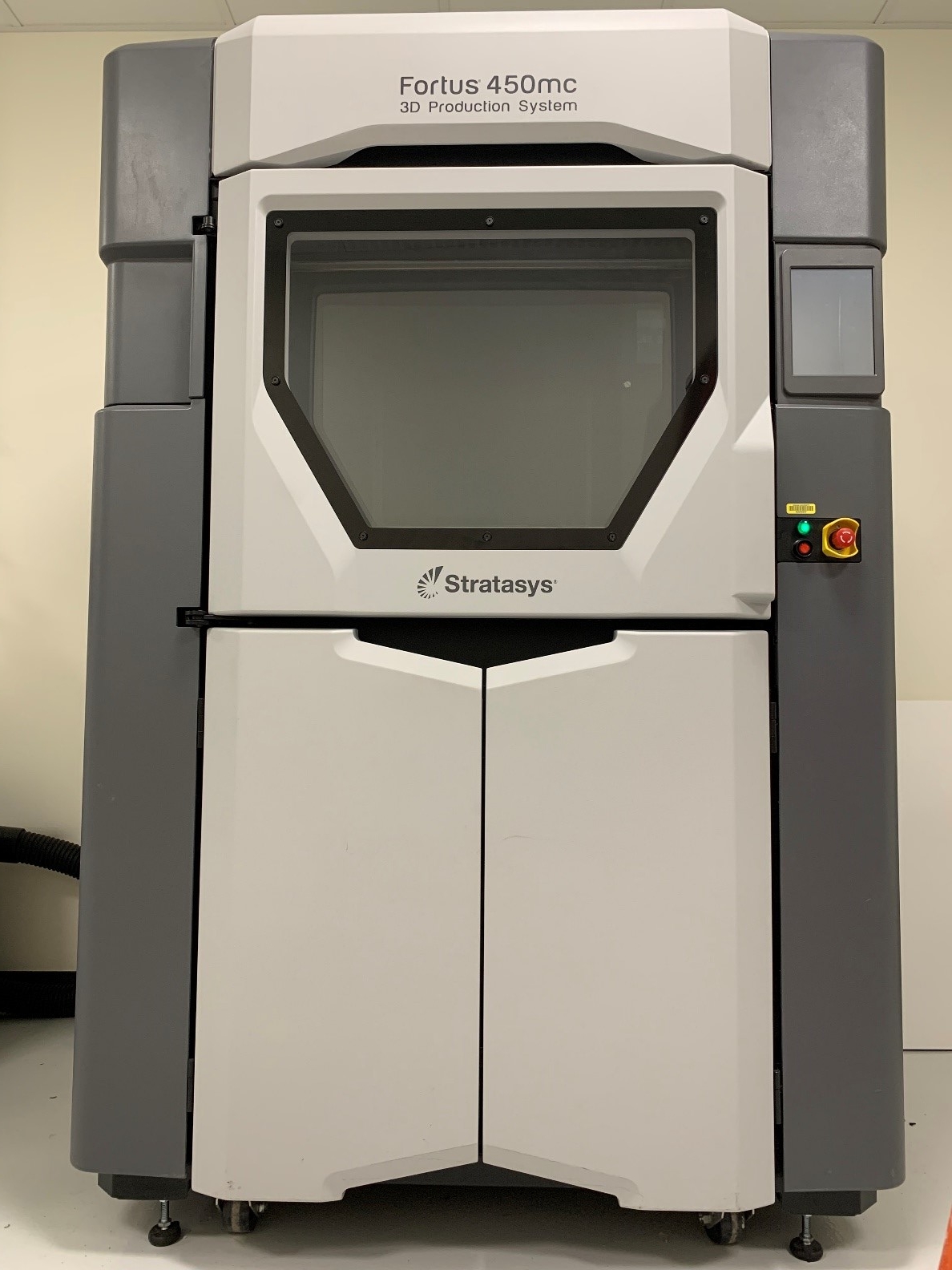

Production-grade Fused Deposition Modeling (FDM) 3D Printer (Stratasys Fortus 450mc) – The Stratasys Fortus 450mc is a thermoplastic-extrusion industrial 3D printer with a build envelope of 406 x 355 x 406 mm (16 x 14 x 16 in.). In addition to standard thermoplastics such as ABS, Ultem, FDM Nylon, ASA, PC, and ST-130, it can optionally run high-performance thermoplastics tailored for specialized production parts in industries like medical, aerospace, research, and defense.

Our machine is currently configured to use translucent natural PC-ISO—a biocompatible grade thermoplastic suitable for pharmaceutical, food packaging, and medical applications. It operates with soluble supports and offers a high-resolution output of 0.127 mm (0.005 in.).

For detailed specifications and additional information, please refer to the catalog entry here.

Research-grade Binder Jetting (BJ) 3D printer (ExOne Innovent+) – Binder Jetting (BJ) is an additive manufacturing process where a liquid binding agent is selectively deposited to join powder particles. Layers of material are bonded to form an object as the printhead strategically deposits the binder into the powder. The job box lowers, a new layer of powder is spread, and the binder is deposited again. Over time, the object is created through this layering process.

Binder Jetting operates similarly to traditional paper printing: the binder acts as the "ink," and the powder layers serve as the "paper," combining to form the final product. This technology supports a variety of materials, including metals, sands, and ceramics. Printed parts are typically cured to remove excess binder and sintered to reduce porosity, enhancing mechanical properties.

Our printer features a print volume of 160 x 65 x 65 mm (6.3 x 2.5 x 2.5 inches) and is equipped with a 30-picoliter voxel printhead and an ultrasonically agitated re-coater. This setup enables successful printing of powders with diminished flow properties or a tendency to agglomerate, while effectively minimizing pluming.

For detailed specifications and additional information, please refer to the catalog entry here.

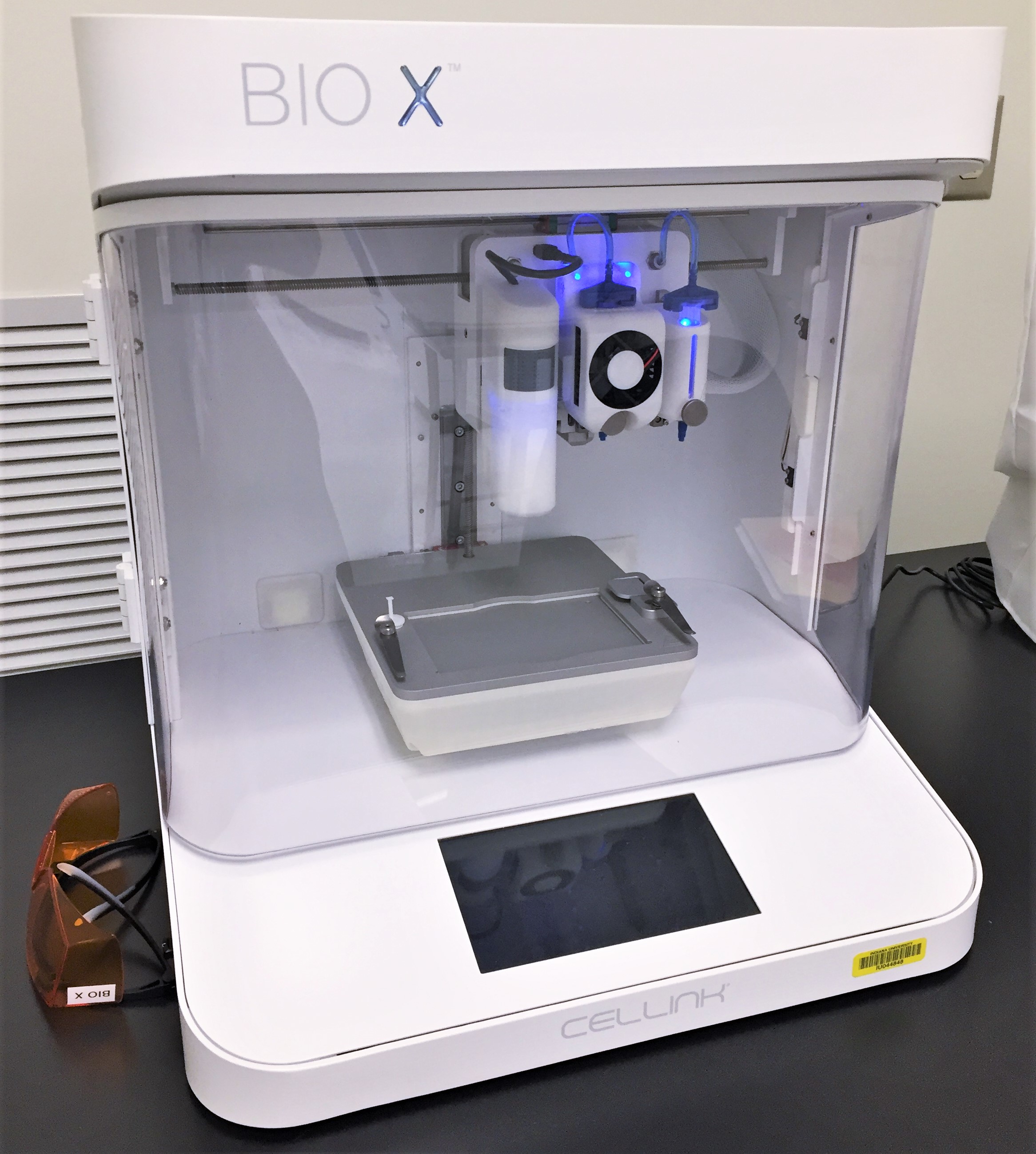

Bioprinter (Cellink BioX) - 3D bioprinting enables the creation of precisely controlled 3D cellular models and tissue constructs by engineering anatomically-shaped substrates with tissue-like complexity. This technology holds the potential to address critical unmet needs in medical research, including applications in cosmetics testing, drug discovery, regenerative medicine, and functional organ replacement. A variety of materials, methods, and cell types can be utilized to fabricate the desired tissue constructs.

The Cellink BioX bioprinter supports printing with thermoplastics, UV-curable, and thermoset bioinks using both jetting and continuous extrusion modes. Bioinks are hydrogel suspensions containing living cells and biomaterials that mimic the extracellular matrix (ECM) environment, facilitating cell adhesion, proliferation, and differentiation after printing.

For detailed specifications and additional information, please refer to the catalog entry here. (access required)

List of equipment by location

Here follows a complete list of the resources available at the facility.Equipment | Manufacturer / model | Use |

Optogear Inc., model OG-510 D | Thermal draw of polymer, soft glass an silica specialty fibers |

Equipment | Manufacturer / model | Use |

Polypropylene fume hood |

| Hydrofluoric acid silica glass etching for preform fabrication |

Explosion and flame protected walk-in fume hood | Chalcogenide glass synthesis and manual butane-oxygen torch processing | |

Mellen

| Chalcogenide glass synthesis, up to 1200 0C | |

Optogear Inc., model OG-440 | Fabrication of silica fiber preforms | |

Victory Inc. | Deposition of chalcogenides, organic semiconductors | |

Form 2 |

|

Equipment | Manufacturer / model | Use |

Vacuum oven | Fisherbrand™ Isotemp™ Model 282A | Polymer backing out and storage |

4’ fume hood |

| General use |

6’ fume hood |

| Polymer processing |

Across International | Polymer sintering | |

| Debinding of ExOne Innovent+ prints | |

Muffle furnace | Across International | 12” x 12” x 16” chamber, up to 1700 0C, for large volume high temperature sintering |

CalNano (AGUS-PECS SS-250Rx) | Nanocomposite and dissimilar materials densification without grain melting | |

Glovebox | Inert | With freezer and two heated antechambers for storage of semiconductors and biomaterials in inert environment |

Baker | For incorporation of cell culture into bioinks, fabrication of preforms in extra-clean environment | |

Cellink Bio X | Bioink 3D printing of tissues | |

Fluorescent microscope | ECHO REVOLVE4 | Bioprints and cell culture metrics |

Thermo Fisher Scientific Revco Ultima II -150°C | Cell culture storage | |

Carbon dioxide incubator | Thermo Fisher Scientific Forma™ Steri-Cycle™ i160 | Cell culture |

Centrifuge | Thermo Fisher Scientific Sorvall ST 16 | Bioink processing |

Form 3B | Biocompatible printing |

Equipment | Manufacturer / model | Use |

Two general use 4’-wide fume hoods | Processing of epoxies and print resins, and for containing extrusion printers with hazardous volatiles | |

Stratasys Fortus 450 mc 3D Production System | Printing translucent polycarbonate fiber preforms | |

ExOne Innovent+ | Printing fiber preform components in powdered materials, such as glass, semiconductors, metals | |

Impregnation unit | CitoVac Struers | Epoxy-embedding of fiber samples |

Polishing station | Tegramin 25 Struers | Polishing of epoxy-embedded samples for SEM measurements |

Labotom 5 Struers | Dissection of preforms | |

Cold Jet i3Microclean | Abrasive cleaning and polishing of chalcogenide evaporator drum and ExOne Innovent+ prints | |

Econoline 36-1 Super | Abrasive cleaning and polishing of chalcogenide evaporator drum and ExOne Innovent+ prints | |

Rheometer | Reologica StressTech HR High Resolution Oscillatory Rheometer | Rheology of polymers and composites |

Equipment | Manufacturer / model | Use |

Optical table | TMC Inc. |

|

Custom-built tapering setup | LG Metalworks (Bloomington, IN), FAMES Lab (IUB-SICE-ISE) | Fiber post processing, such as axial patterning by capillary breakup |

Equipment | Manufacturer / model | Use |

L-shaped optical table | TMC Inc. |

|

High-end optical inspection microscope with phase contrast and DIC | Laxco LMC500 | Inspection of fiber samples with high resolution and contrast, including detection of stresses. |

Optical profilometer | Beam Gauge Ophir | Laser beam profile measurements |

Optical spectrometer | Thorlabs |

|

Large area thermopile detector + power meter console | Thorlabs |

|

Coherent Diamond C20a |

| |

Ytterbium Laser | Neptec OLFL-CW-1064-30 Fiber Laser |

Equipment | Manufacturer / model | Use |

Intelitek BenchMill 6100 |

| |

Comsol and Solidworks station | Dell | CAD design and numerical simulations |

Automatic Band Saw | Ironware PROXXON 27172 MICROSEGA |

|

Two workbenches with general equipment and soldering stations |

|

|