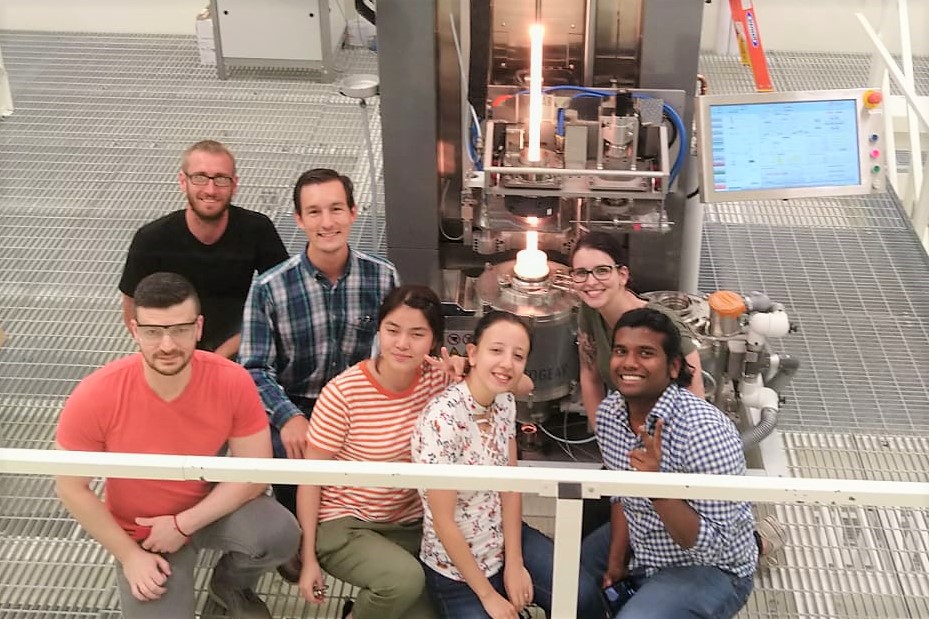

FAMES Lab takes FOX59/CBS4 on an exclusive tour of their facilities

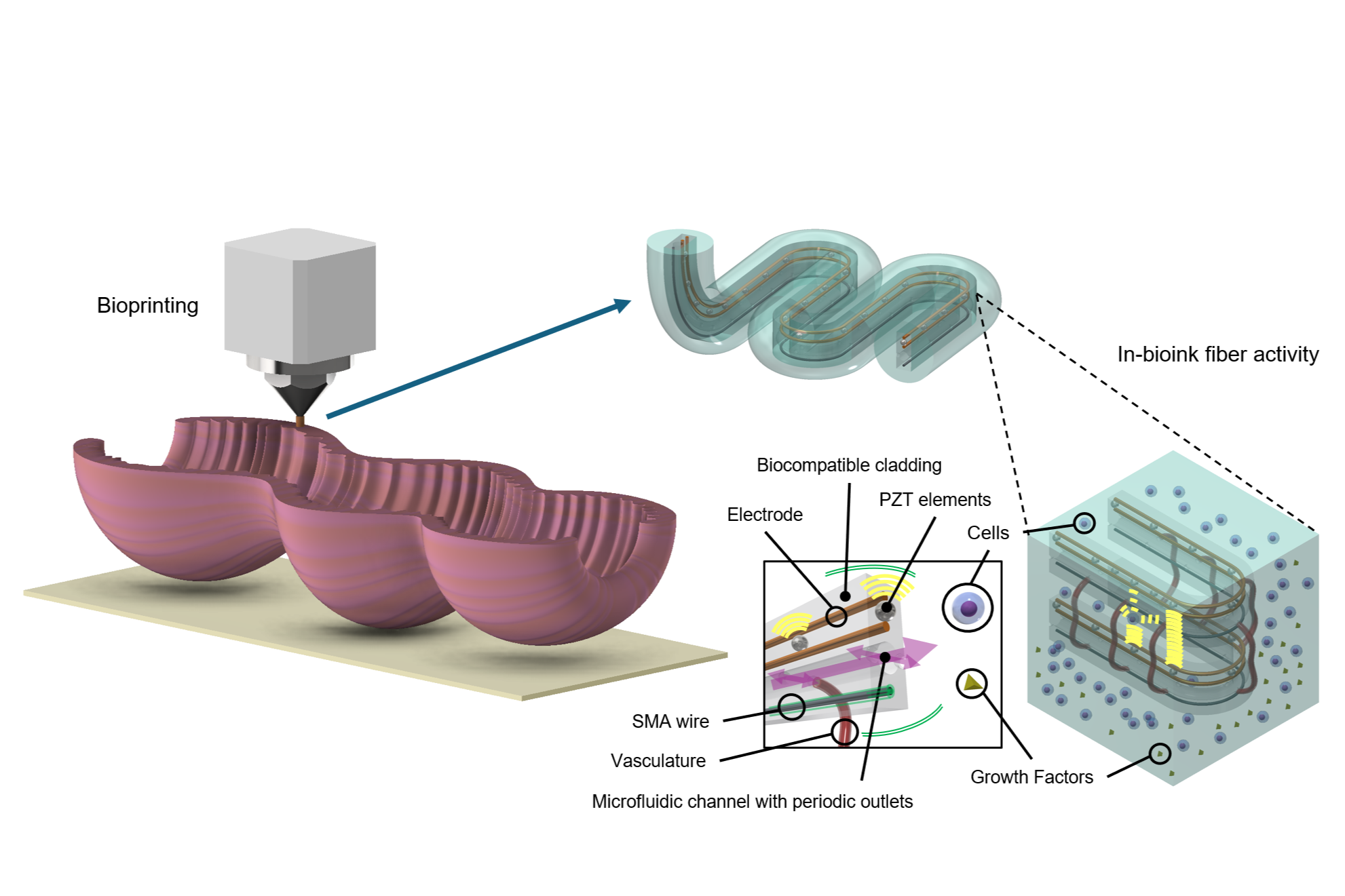

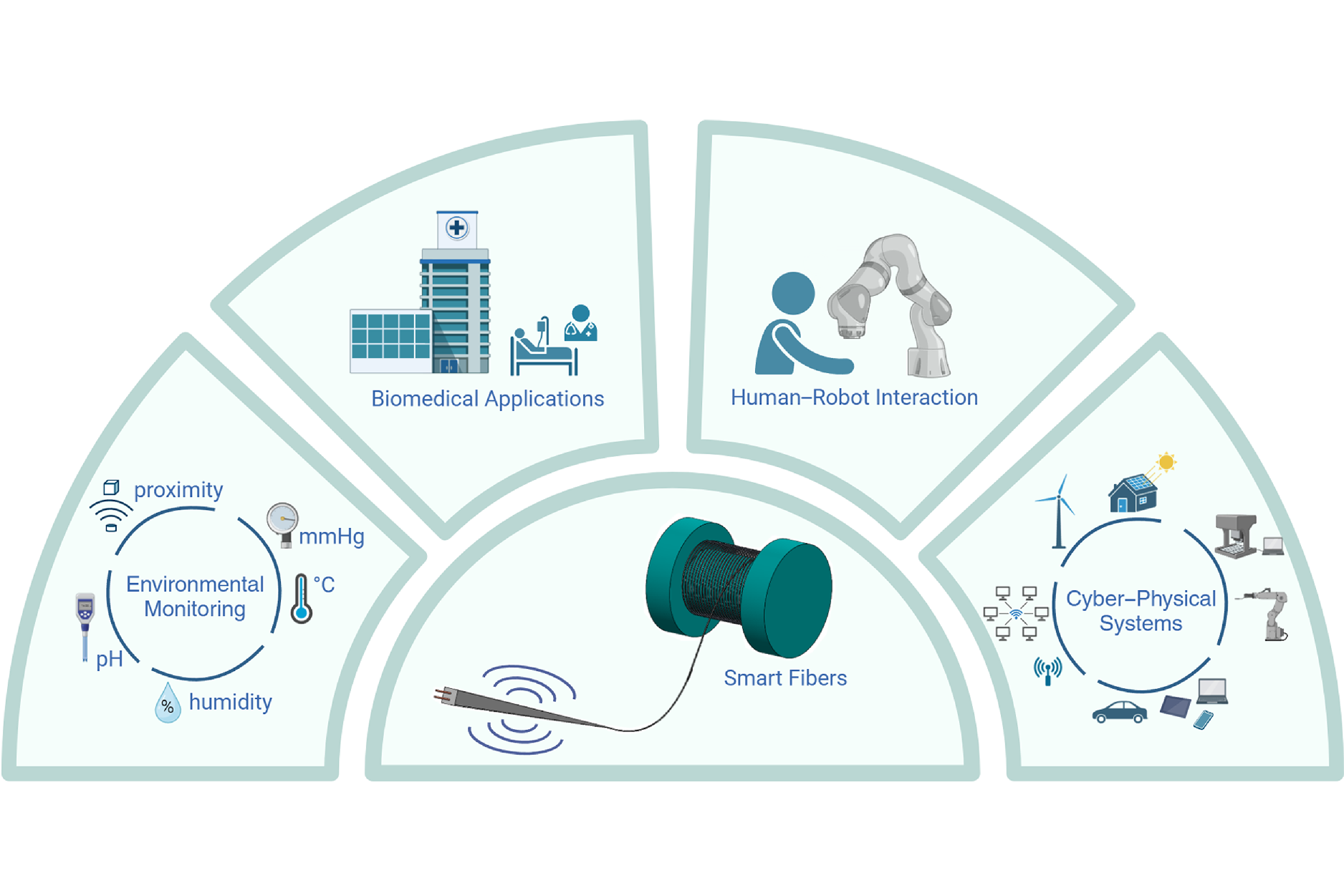

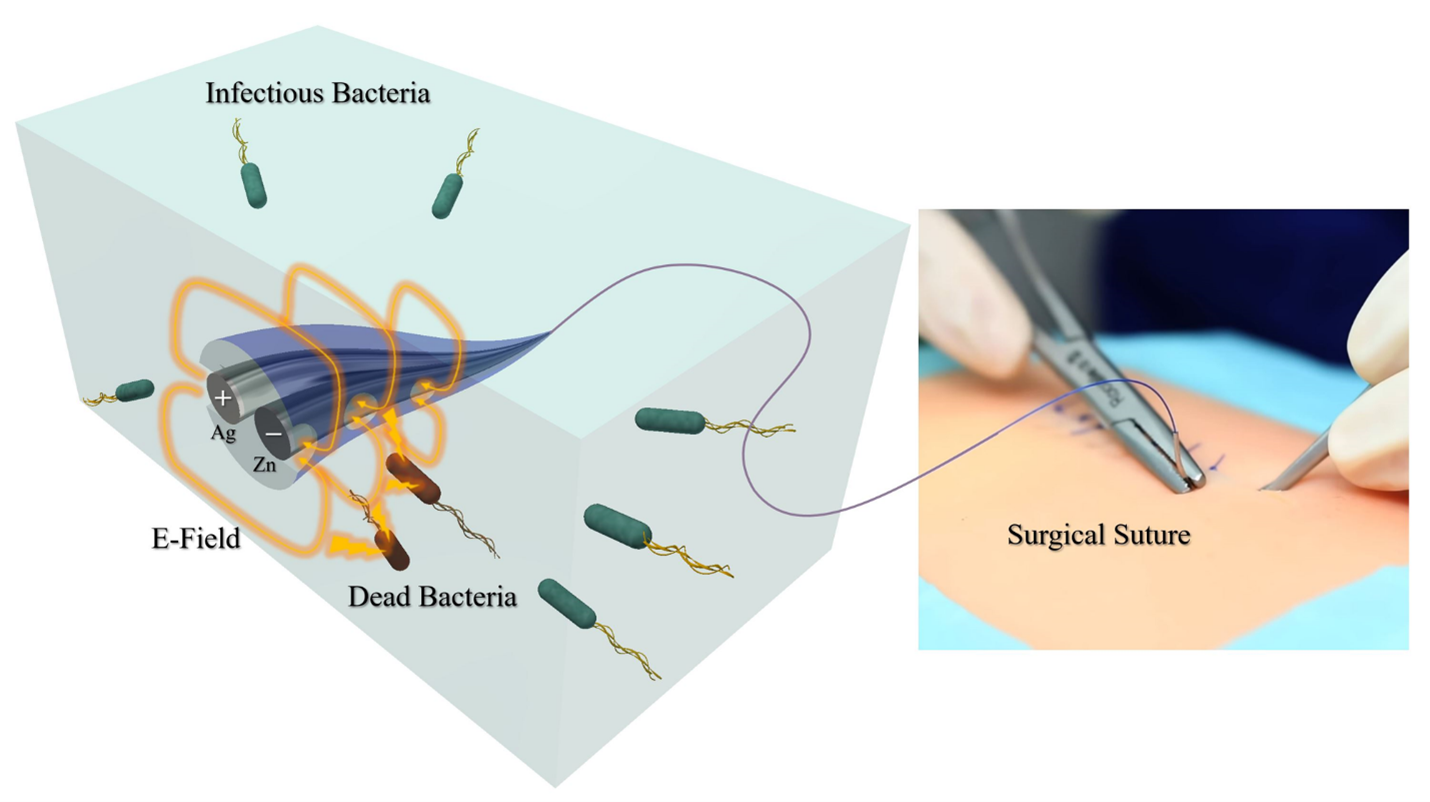

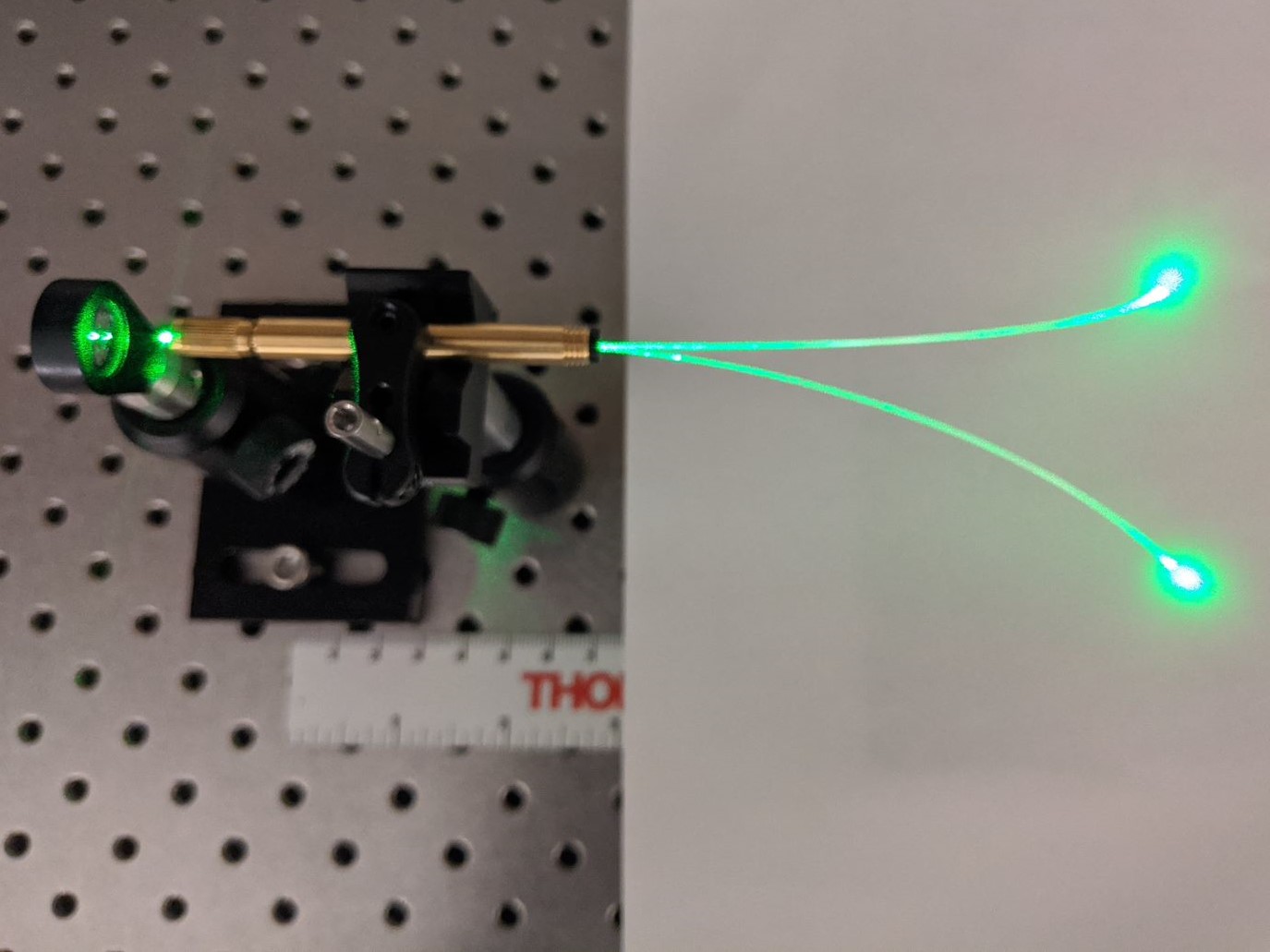

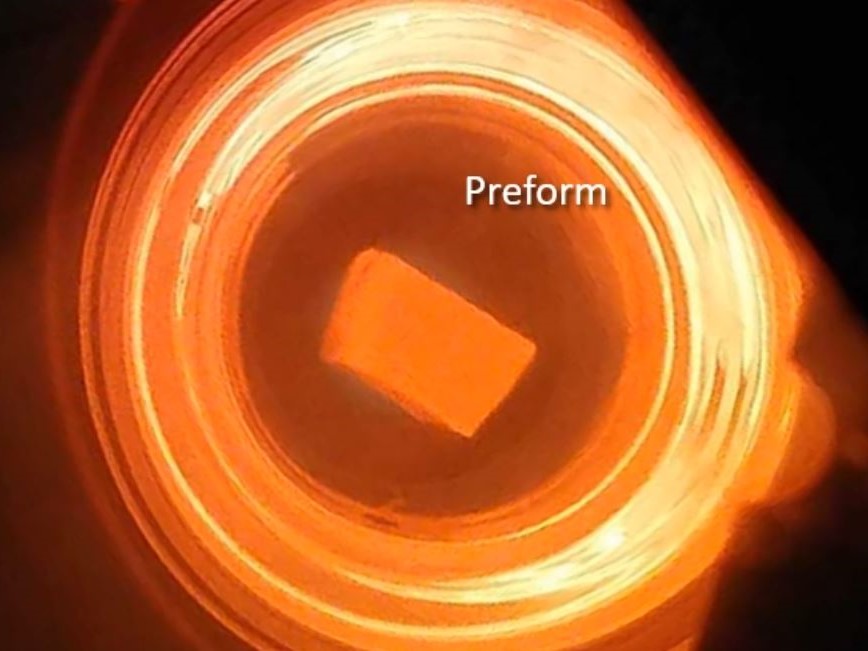

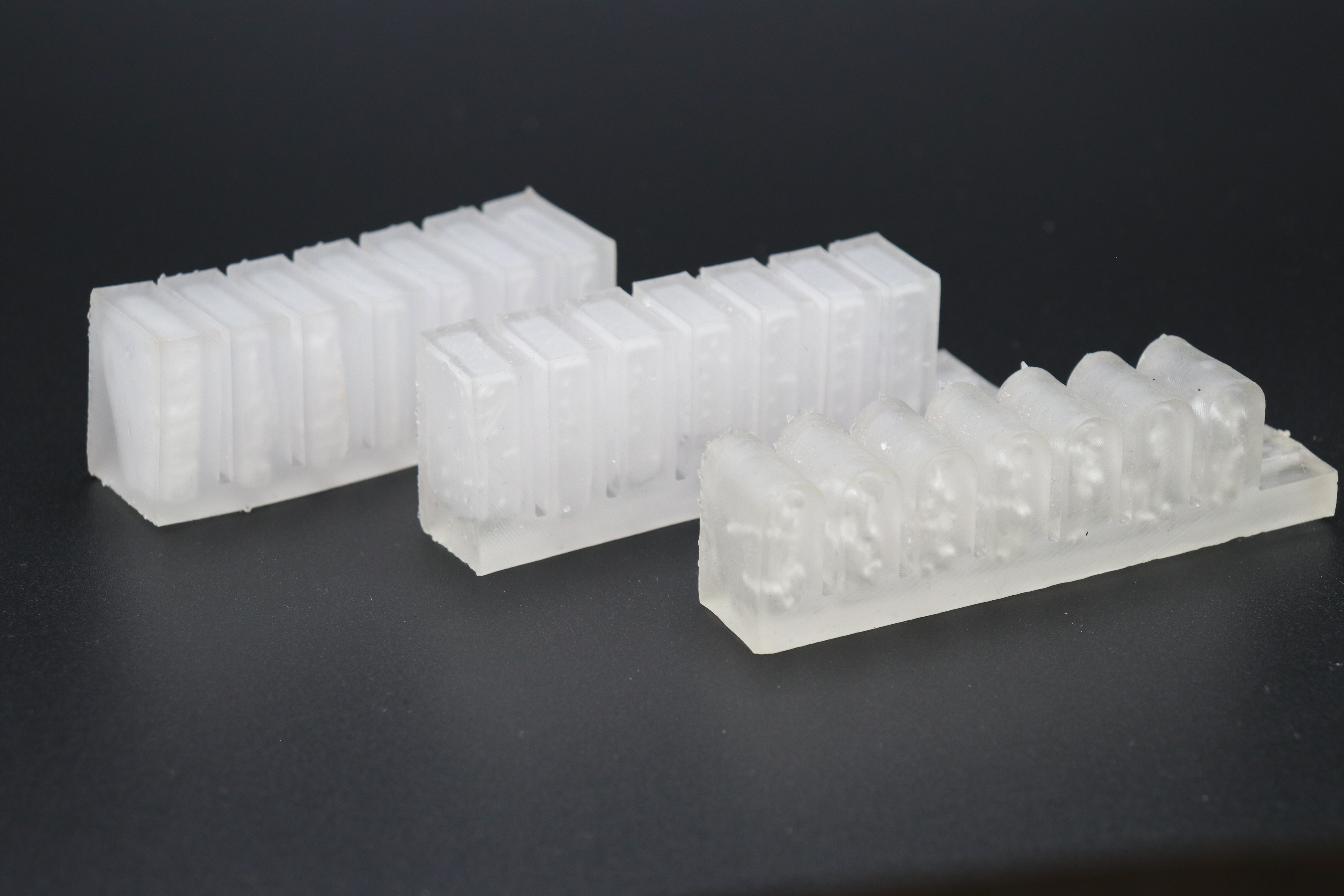

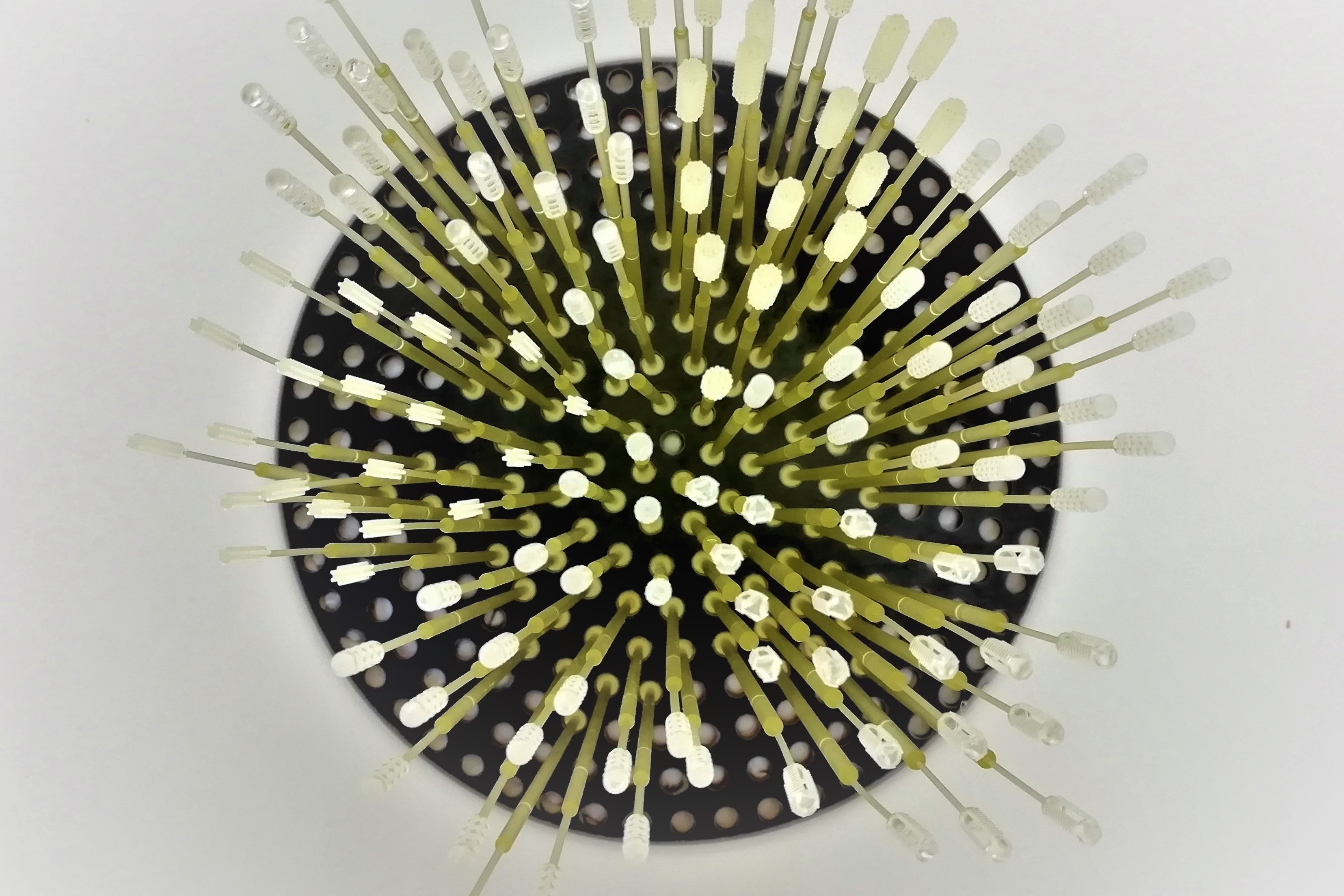

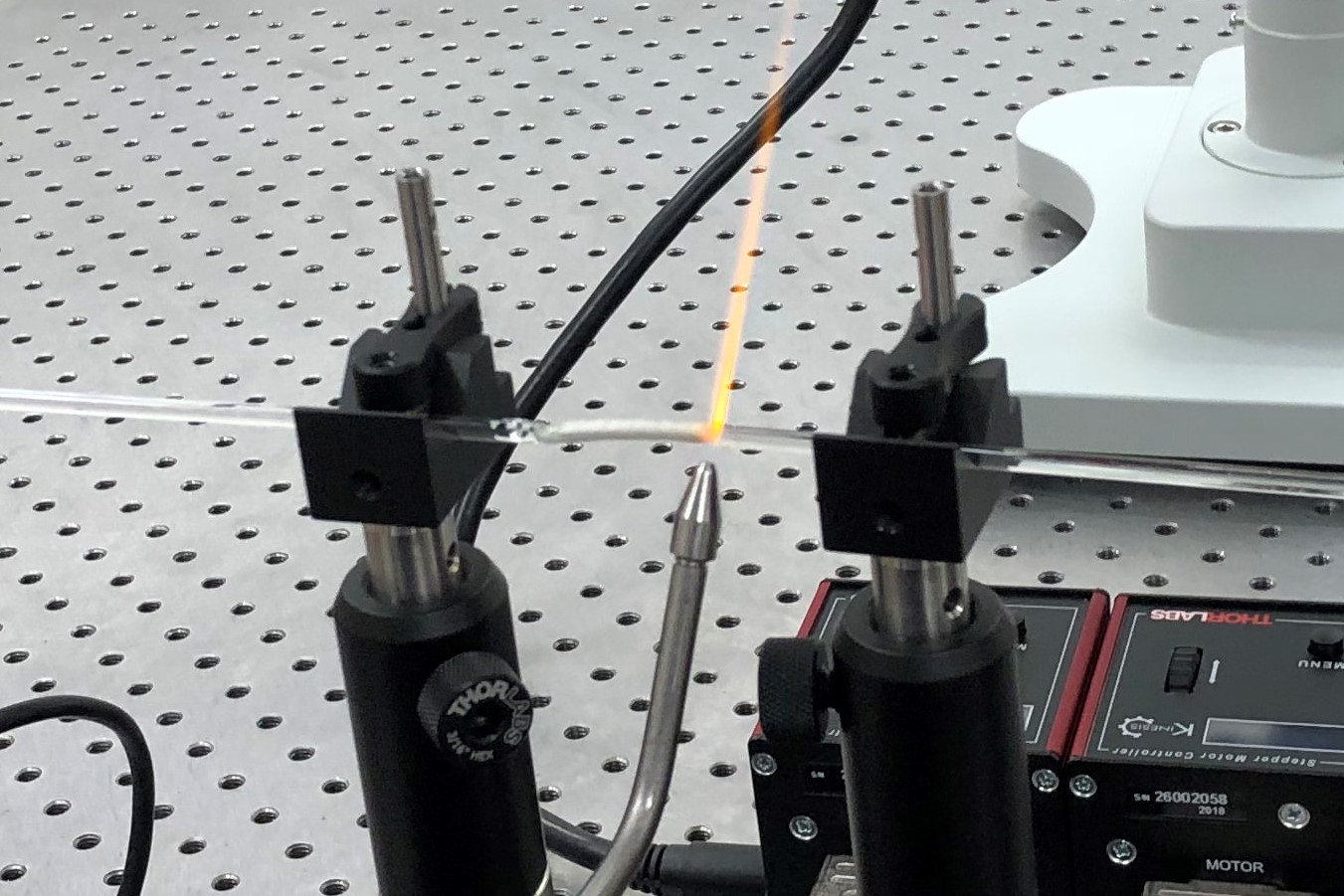

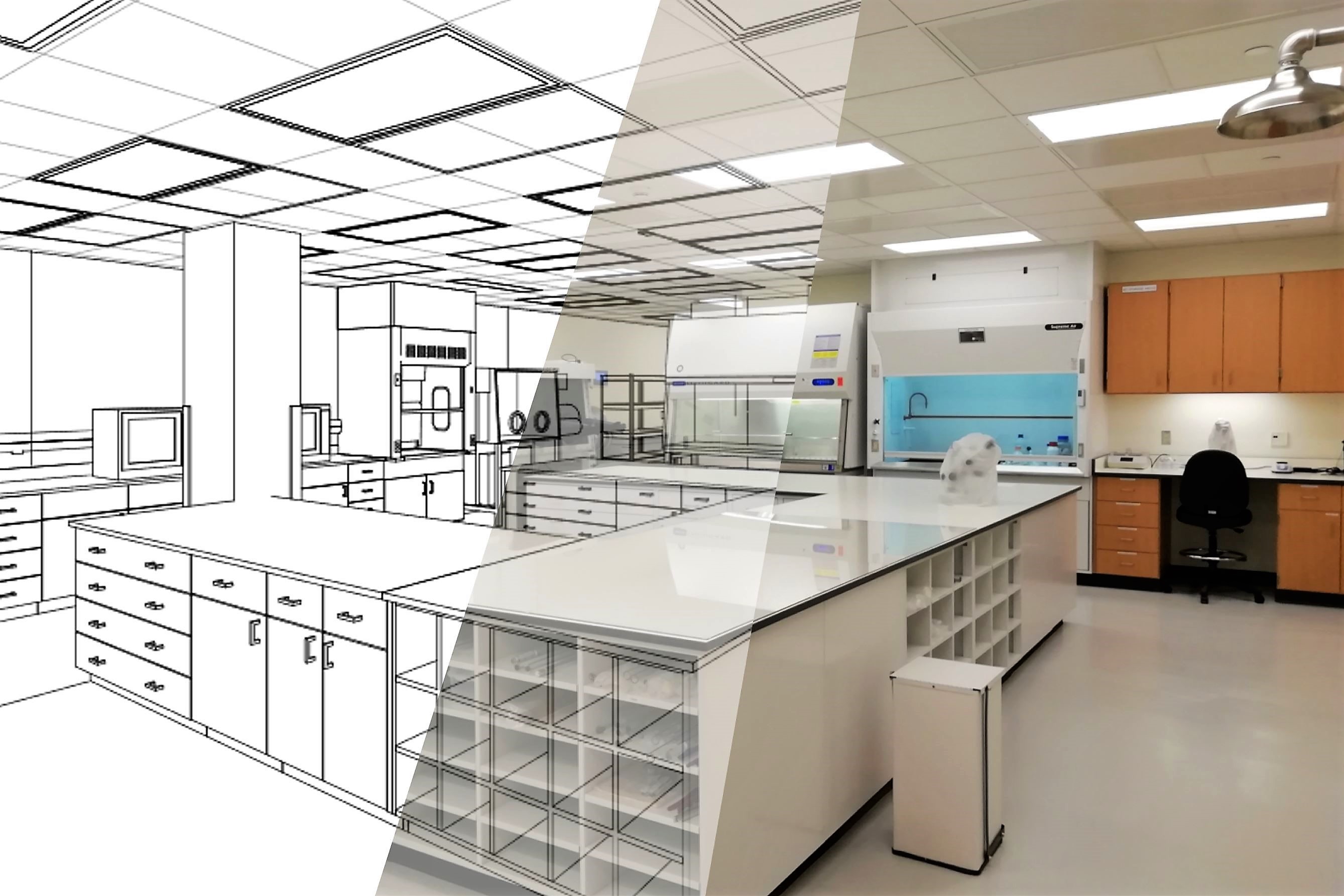

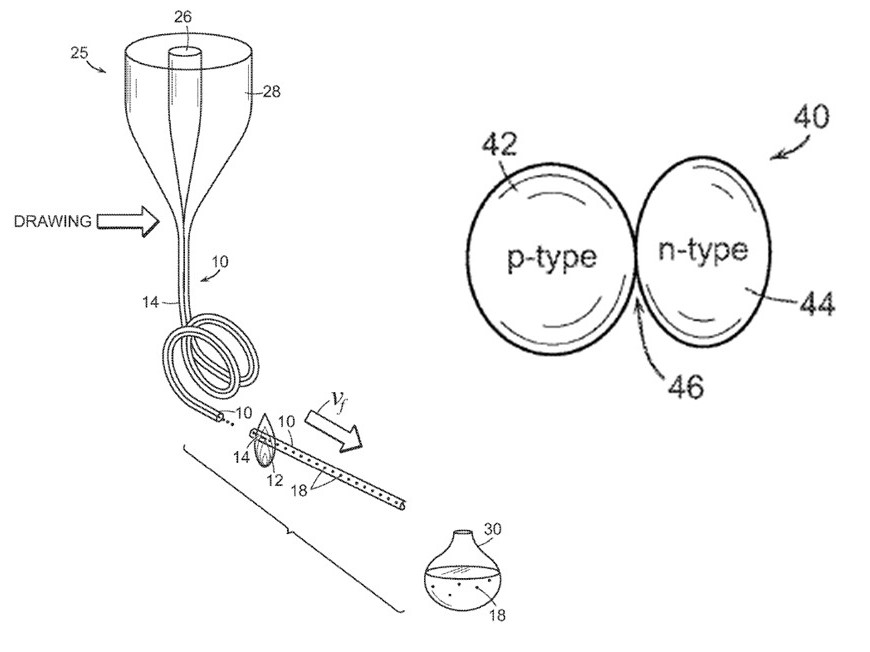

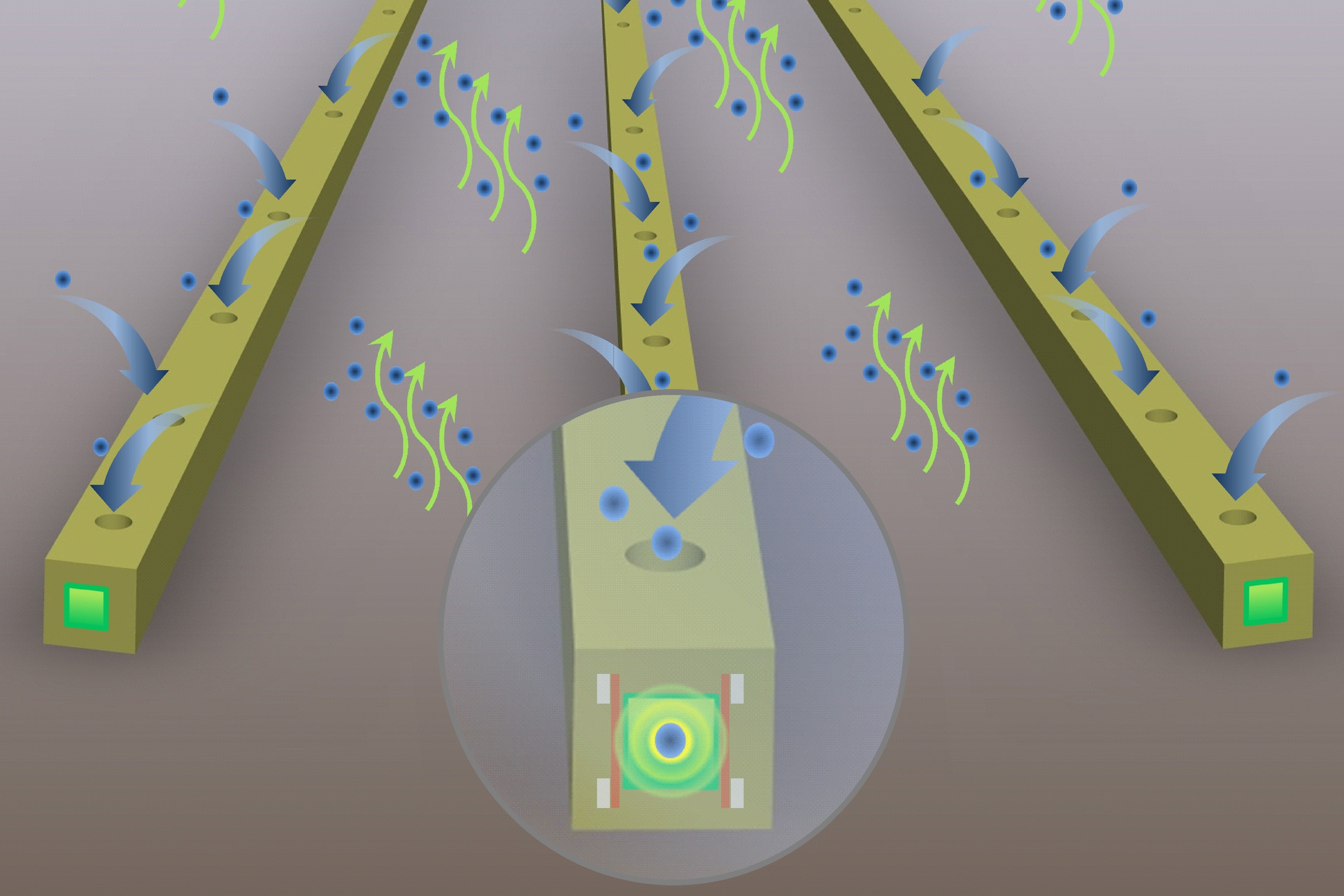

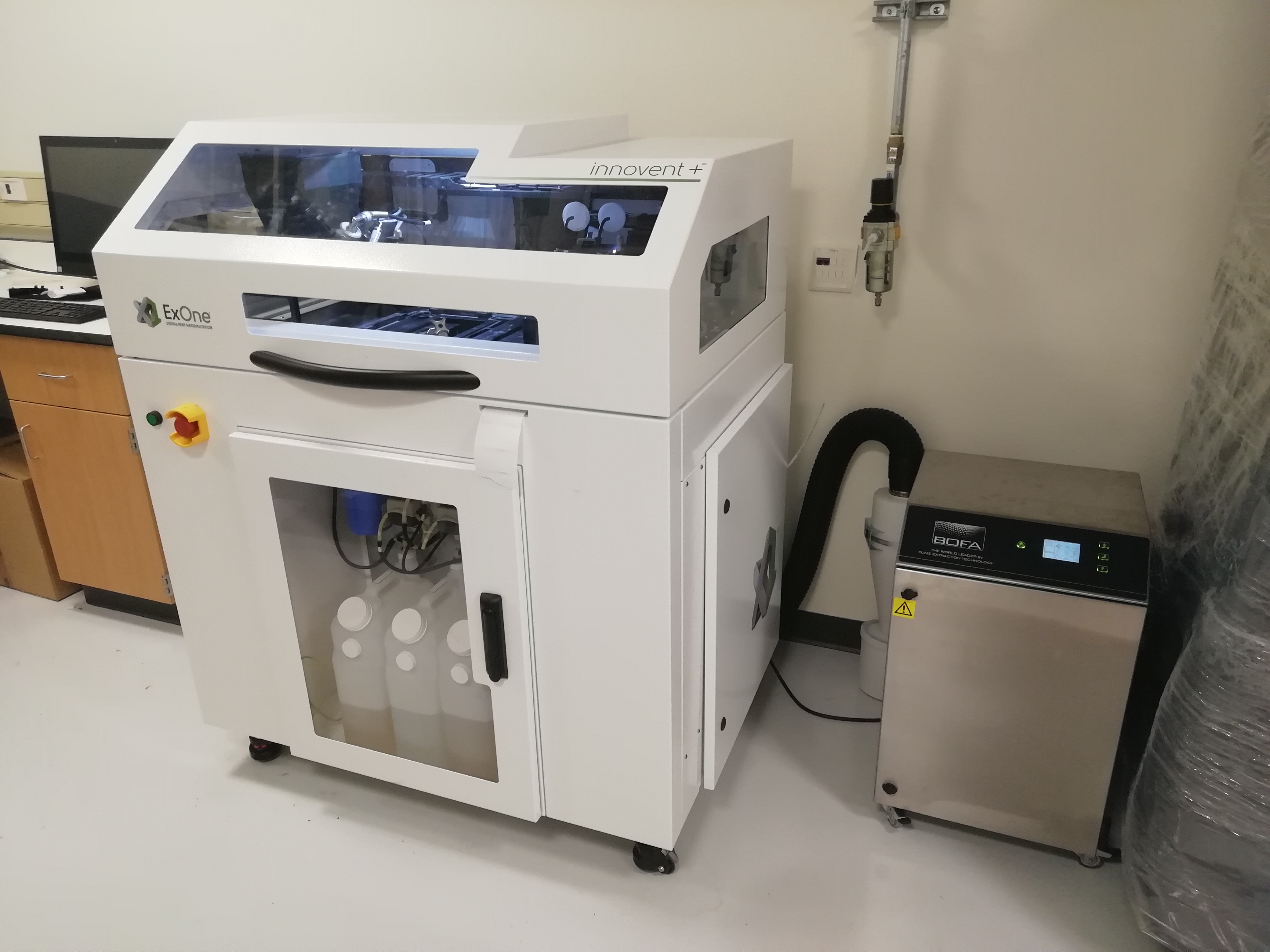

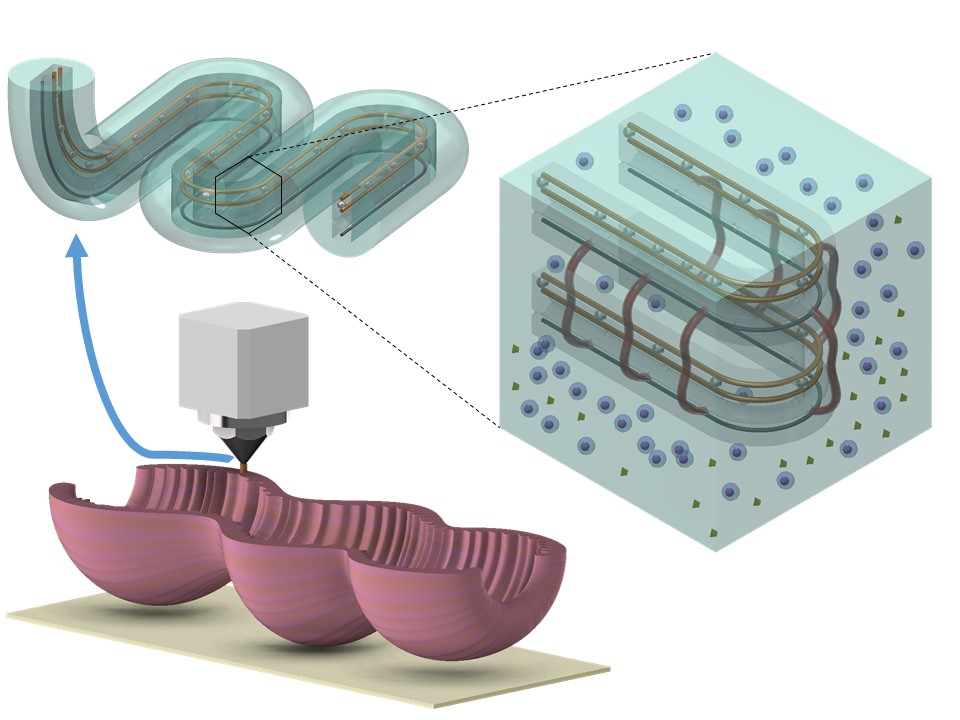

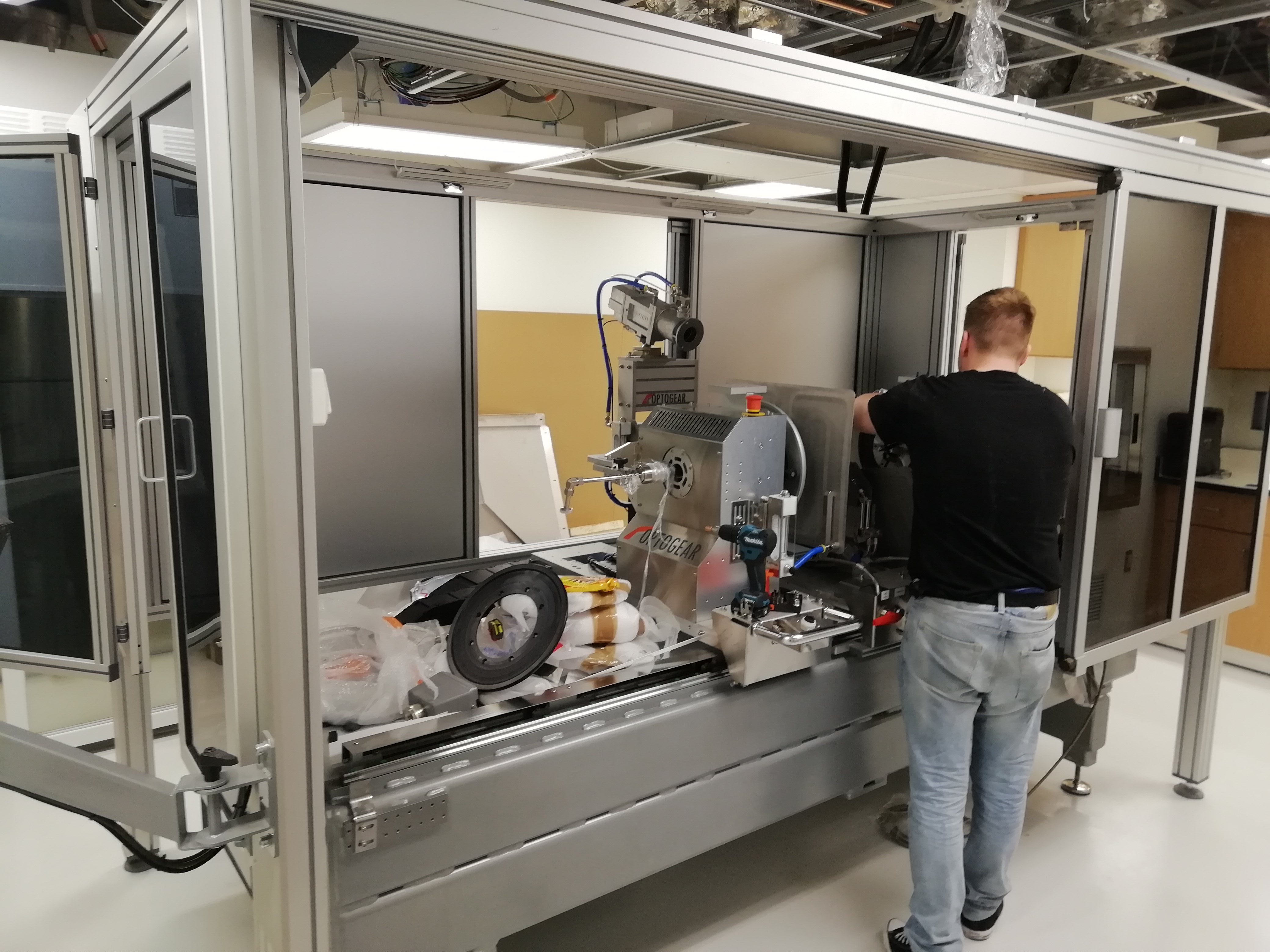

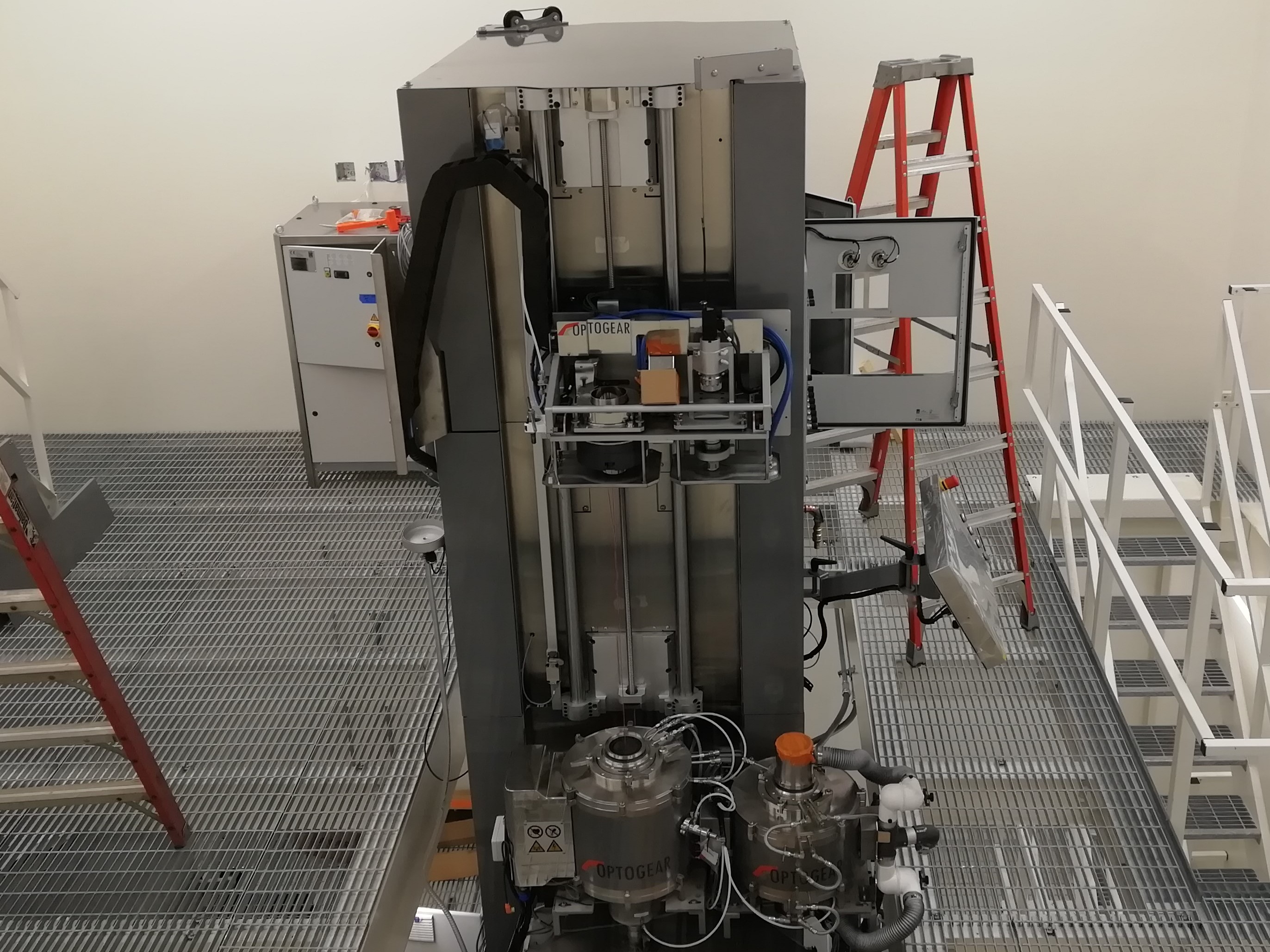

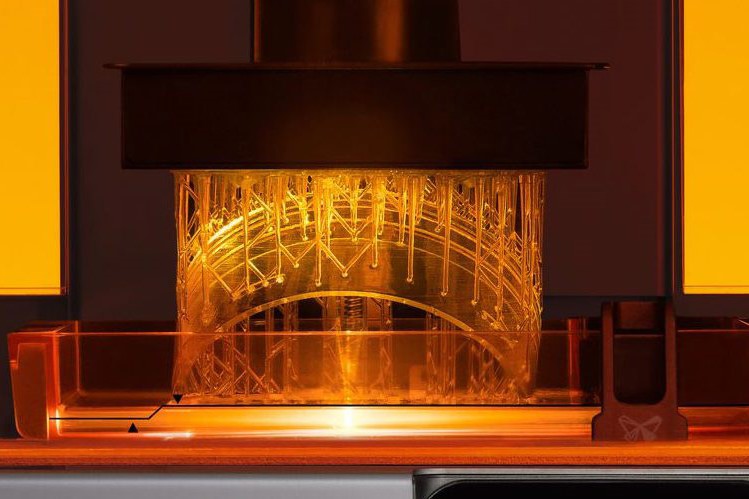

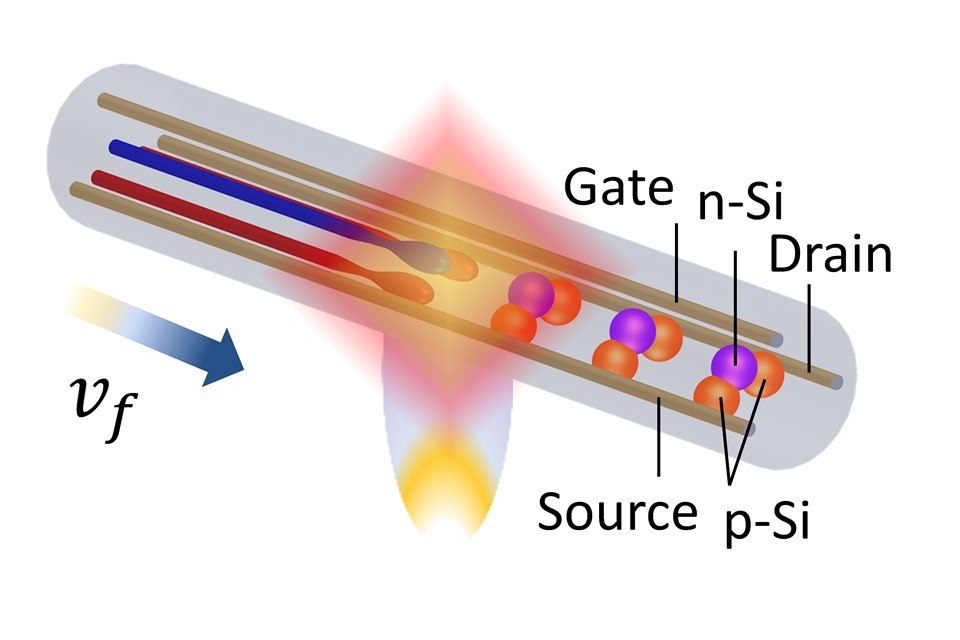

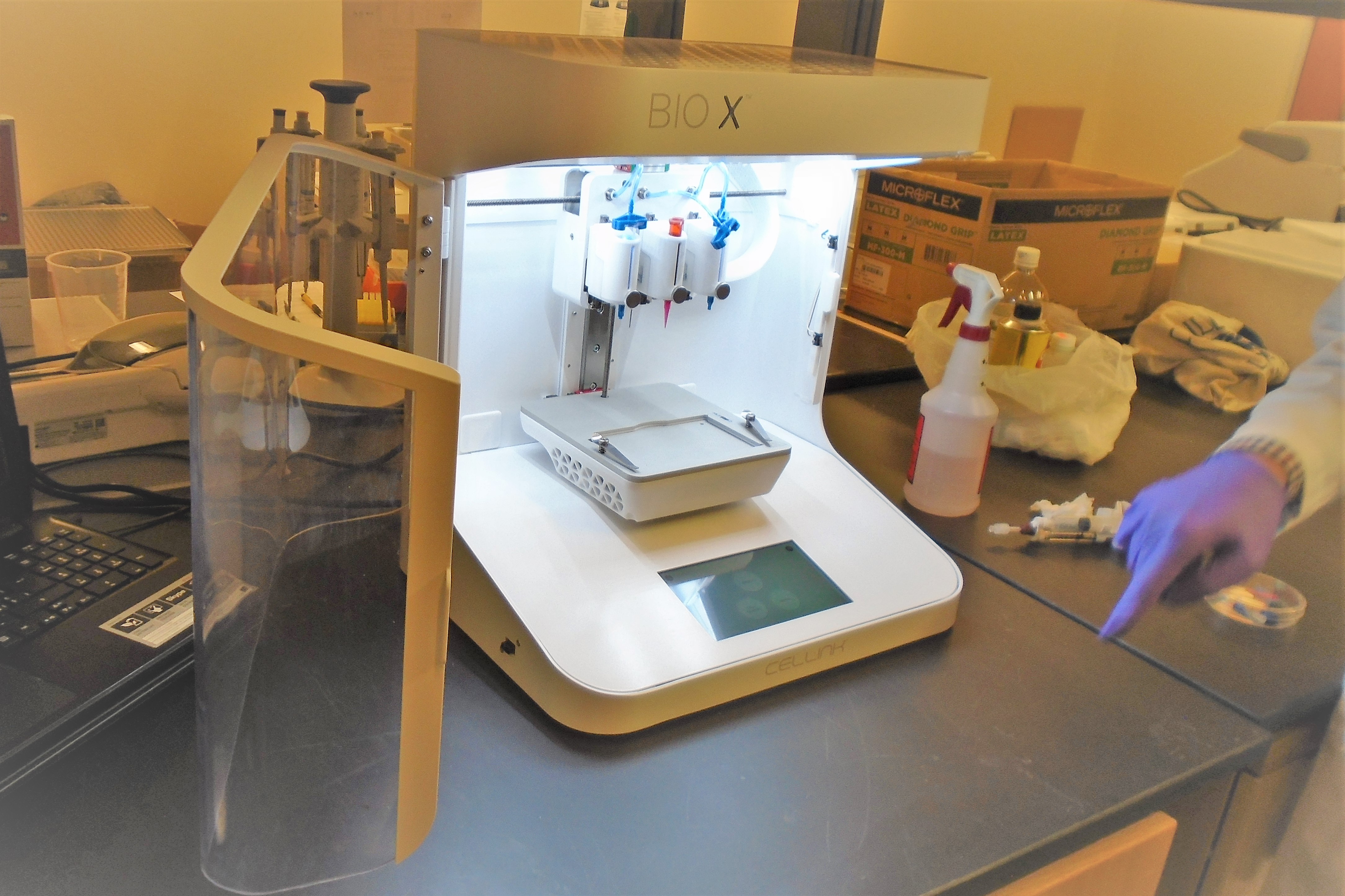

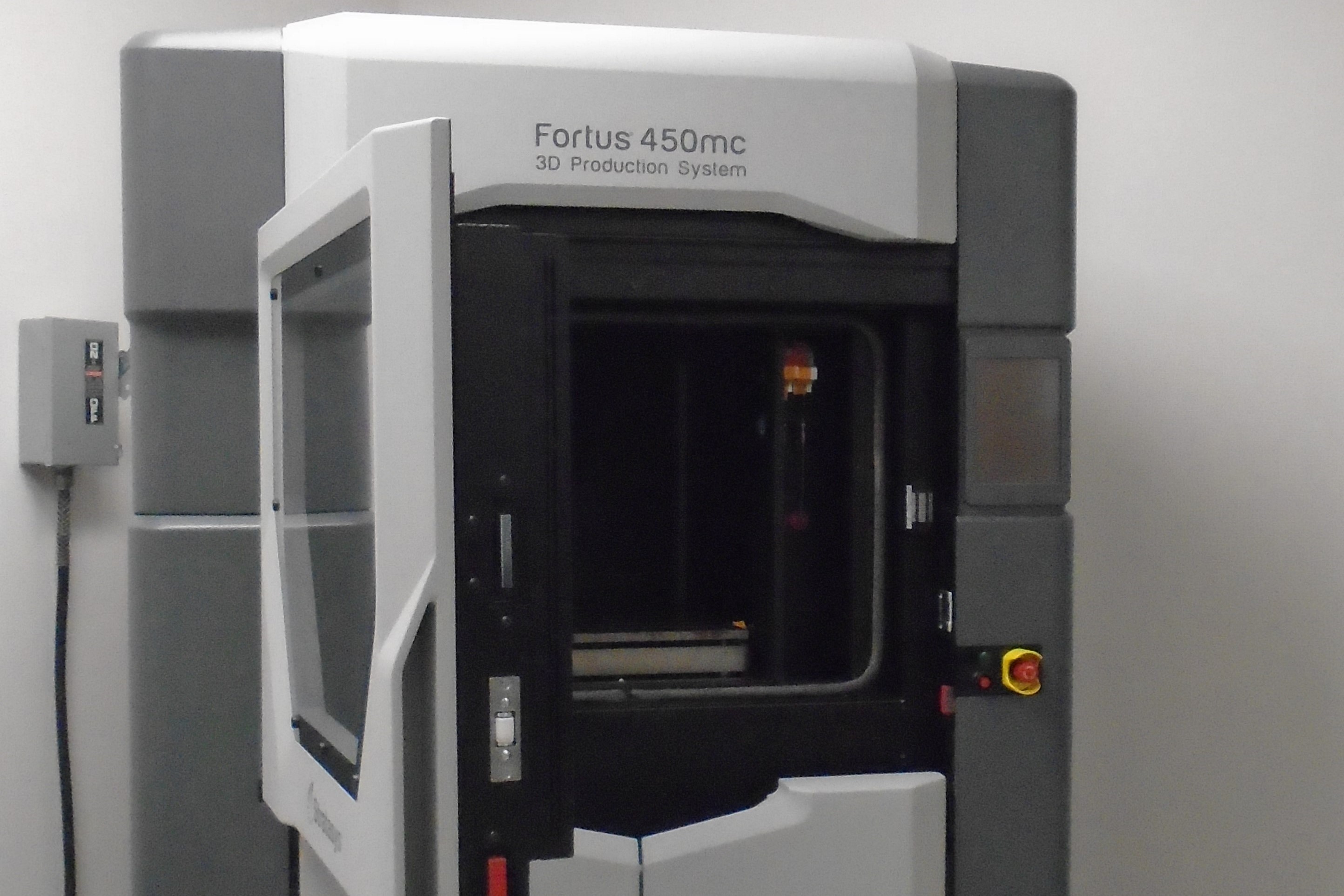

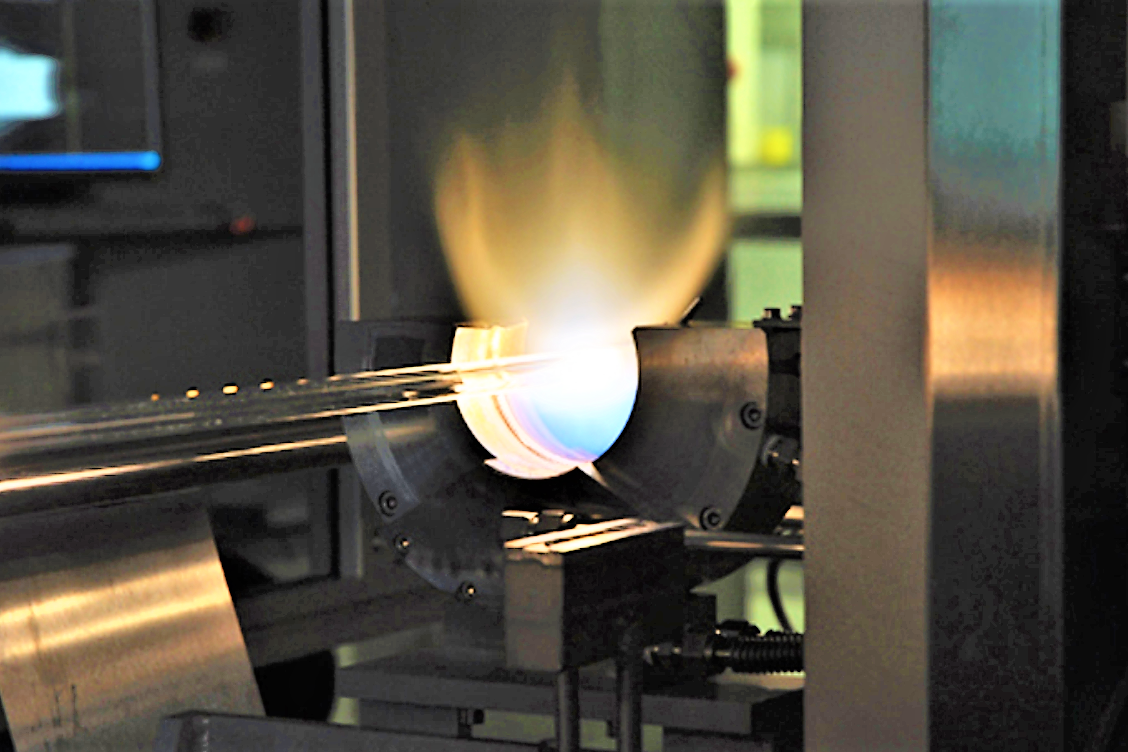

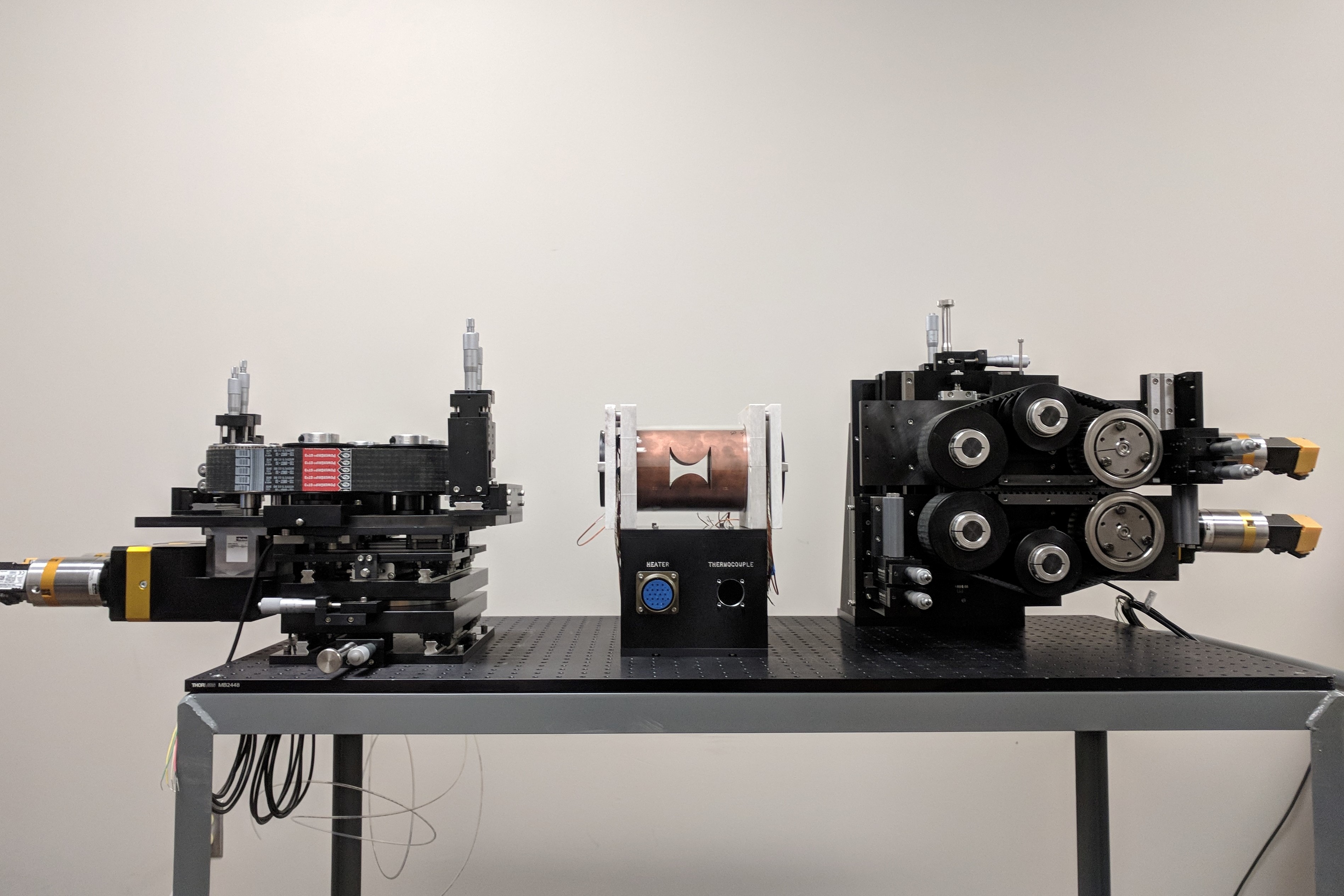

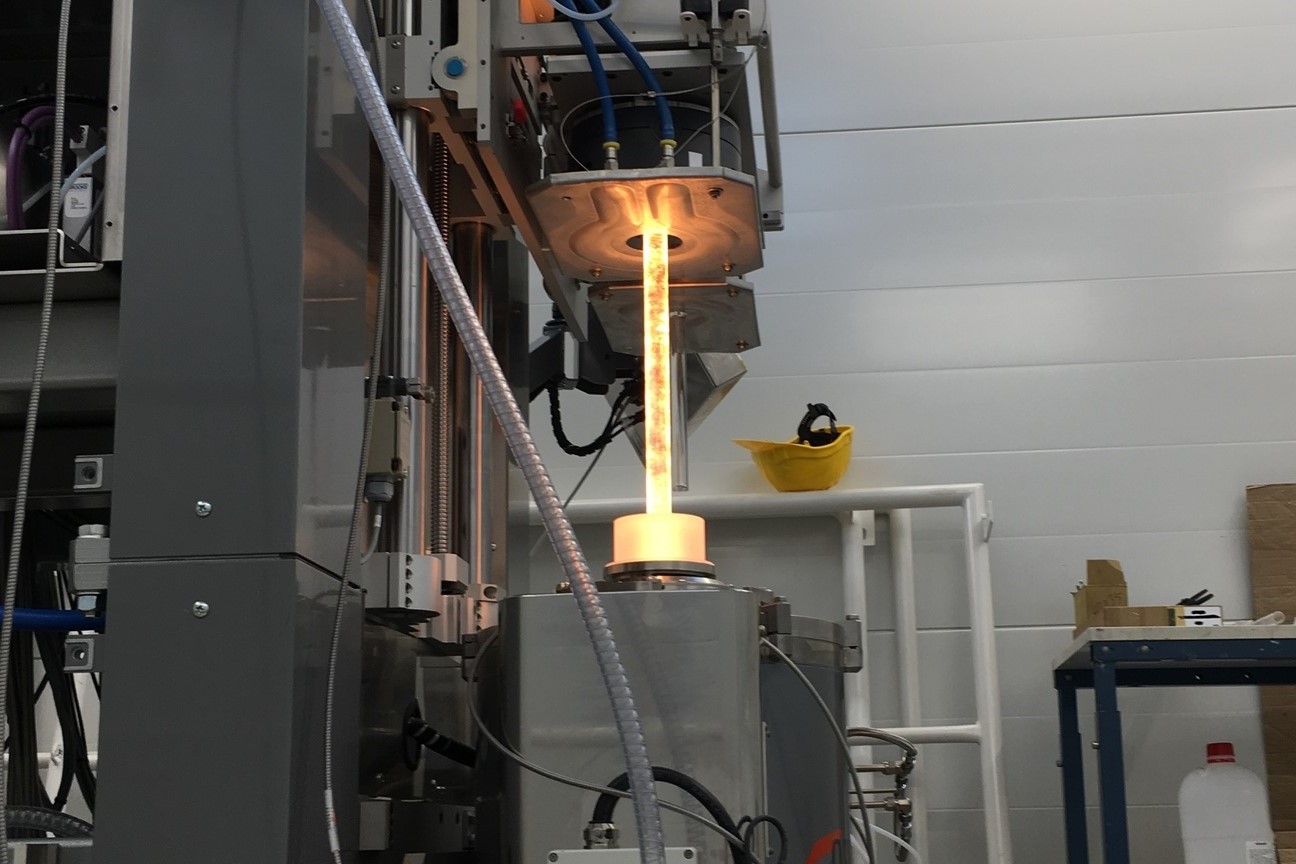

Officials with the FAMES Lab, or the Fibers and Additive Manufacturing Enabled Systems Laboratory, recently took FOX59/CBS4 on an exclusive tour of their facilities, including showing off a new self-aware catheter system with a wire guide.