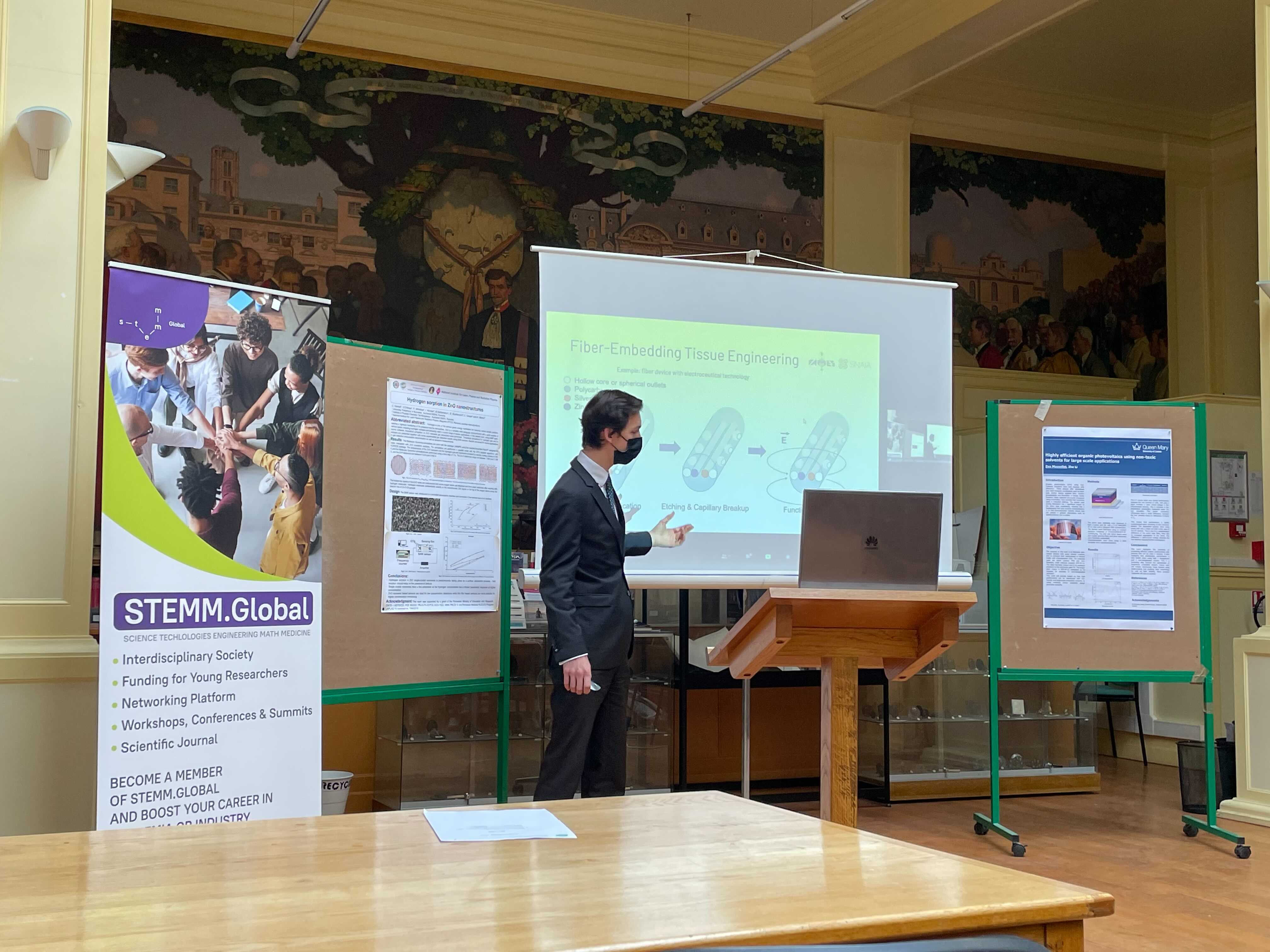

Louis van der Elst was award Best Student Presentation Award by STEMM Global Scientific Society at their Smart Nanomaterials: Advances, Innovation and Applications (SNAIA) 2021 conference, along with a £300.00 travel voucher for any STEMM Global Conference. His presentation titled “Functional Fibers and Textiles for Biomedical Engineering” covered advances in bioprinting and its challenges, Very Large-Scale Integration (VLSI-Fi) technology, and fiber-embedding tissue engineering.

Although nascent, regenerative medicine is gaining momentum with constant innovations of cellular-level solutions for human healthcare. Functional fibers and textiles (FFT) have a unique contribution to play in understanding the world of cells and resolving the challenges that are associated with their manipulation such as 3D bioprinting, genetic modification, tissue maturation and more. Multimaterial fiber devices can help address challenges in tissue biofabrication such as:

- the trade-off between resolution and volume

- the morphological and mechanical properties

- the selection and delivery of cell density, types, and population ratios

- the proliferation, interaction, differentiation, and cell movement

- the inhibition of bacterial contamination in cell cultures

- the introduction of different signaling pathways and/or cell growth factors

- the self-assembly and homeostasis

- the management of dangerous and infectious by-products

At the Fibers and Additive Manufacturing Enabled Systems Laboratory (FAMES Lab), the bioengineering subgroup focuses on tackling these challenges by designing a variety of fiber devices. FFT are designed to hold bioactive properties through microfluidics and porosity, for fluid flow; or a variety of core electroactive materials, for function or actuation. Specifically, recent work at the FAMES Lab includes the development of fiber that disturbs quorum sensing in bacteria to mitigate the infection of a tissue, having applications in surgery for deep chronic wound healing, as well as in bacteria-free bioprinting and tissue maturation. These fibers are fabricated using biocompatible materials in 3D printed polycarbonate preforms and use the principles of electroceutical technologyto function.