This week celebrates Veda and Vakar's first place in the fifth annual Cheng Wu Innovation Challenge with their creation, the M3DE Pro, A pneumatic upper limb prosthetic. They tied in first place with another team’s NeuroNursing startup for quality of care for Alzheimer's disease patients, receiving $7,500 each to create a product out of their innovative designs. It is the second consecutive year that FAMES lab members apply and win at this competition; however this year, due to the COVID-19 pandemic, teams pitched their work to judges via eight-minute-long videos on April 9, and Dr. Brown, Director of the Shoemaker Innovation Center, selected the winning teams based on the judge’s feedback. Much innovation has been through biomimicry and bioengineering courses in the Department of Intelligent Systems Engineering (ISE) do a great job of covering bio-inspired actuators and machines. Veda and Vakar are two students that have decided to explore the methods of rapid prototyping in fabricating pneumatic-actuated bio-inspired prosthetics. Veda is a Ph.D. student in Nanoscale and Molecular Engineering, a member of the FAMES Lab, and Vakar is a graduate student in Computer Engineering. Both are part of ISE at Indiana University. Here is their story.

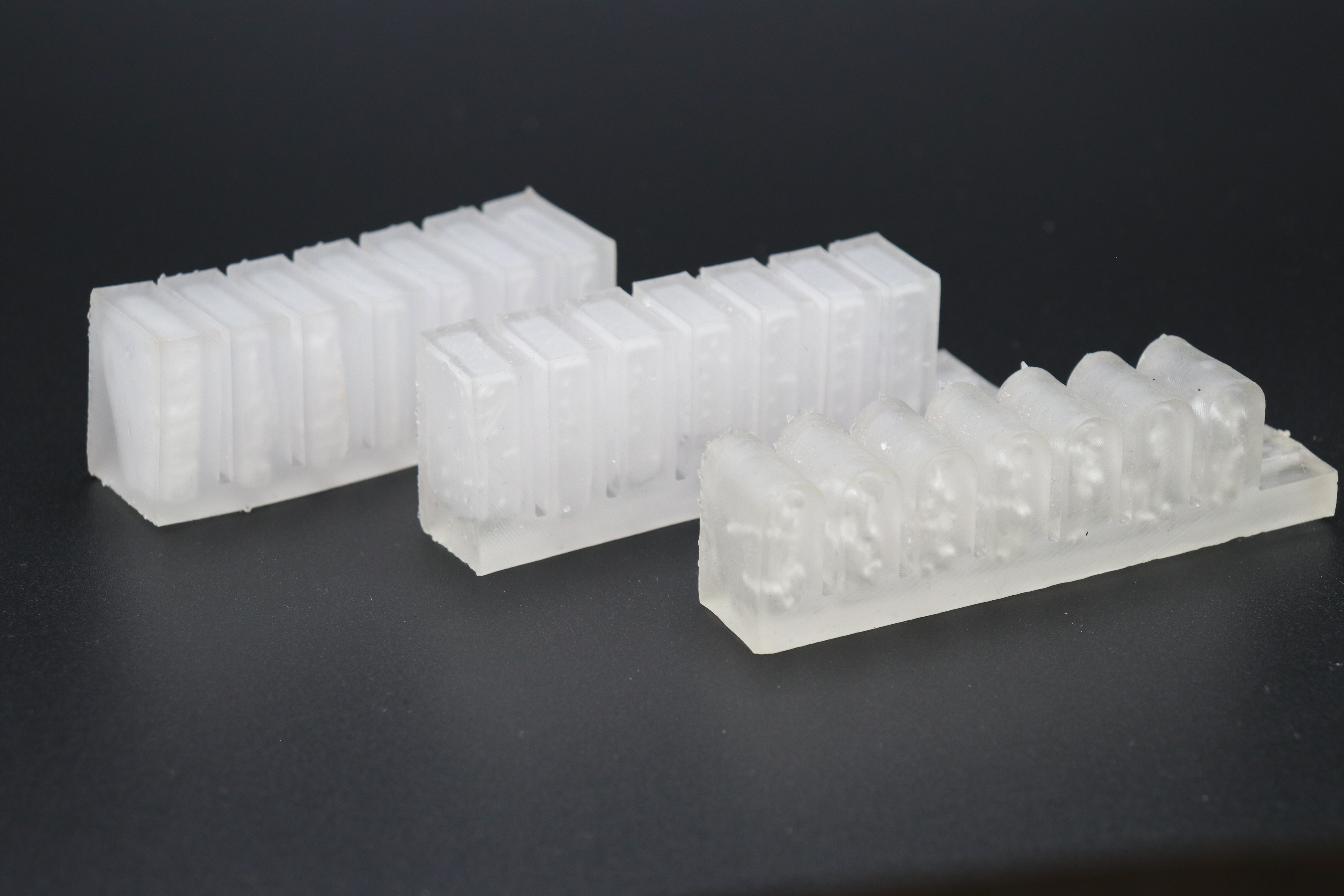

M3DE Pro (Modular 3D-printed Elastomeric Prosthetics) is an economically accessible modular functional prosthetic arm built using elastomeric actuators that can replicate the most frequently used human grasps. M3DE Pro is designed to make upper limb prosthetics affordable and readily available for amputees. It aims at generating value in the lives of those who need it the most.

The work on this project dates back to Veda’s final project for Dr. Guo’s class, Biomedical Microelectromechanical Systems, titled ‘Soft robotics with acoustic heating actuation’. The following semester Vakar joined Dr. Bondesson’s class, Introduction to Bioengineering, and began to work on a biomimicry project concept with applications in prosthetics. However, the ideas of the two students only came to life using the skills learned in the Rapid Prototyping course by Dr. Gumennik on they were able to further develop a concept design with a partially functional 3D printed gripper. After the class ended, they continued to work on the project and saw Cheng Wu as an opportunity to display their work. Throughout their journey in the Cheng Wu Innovation Challenge, Dr. Gumennik was kind enough to offer continued support and resources from the FAMES lab. They are also thankful for the intellectual guidance of Dr. Ward in fluid mechanics.

Moving forward, they plan to develop the design further and make a fully functional prototype. With the funds received, they will primarily spend it on purchasing simulation software and raw materials allowing them to make and test various prototypes. With the help of Mr. Jim Dewees, founder of the Prosthetics Center of Indiana, Vakar and Veda intend to prototype their creation with clinical patients and optimize the design based on patient feedback. With a working prototype, they plan to apply for more funding to make M3DE Pro available in the market. In parallel, they Vead and Vakar also made it to the semi-finals of the Clapp IDEA Competition hosted annually by the Kelly School of Business Johnson Center for Entrepreneurship. Below feature videos of their innovative design.