As we all observe the rapid development of the recent COVID-19 pandemic worldwide, it is paramount that we learn the lessons from those first affected by the virus and do our best to brace for the incoming storm. As of April 8th, the State of Indiana has registered 5,943 positive cases for the novel coronavirus and 203 deaths. Shortages in personal protective equipment such as face shields and masks, as well as of ventilators and test swabs have been reported in most places affected by the pandemic and are expected to hit the state in the coming weeks. Several online sharing platforms have formed to answer medical needs during the crisis, such as the NIH and GetUsPPE, nation-wide.

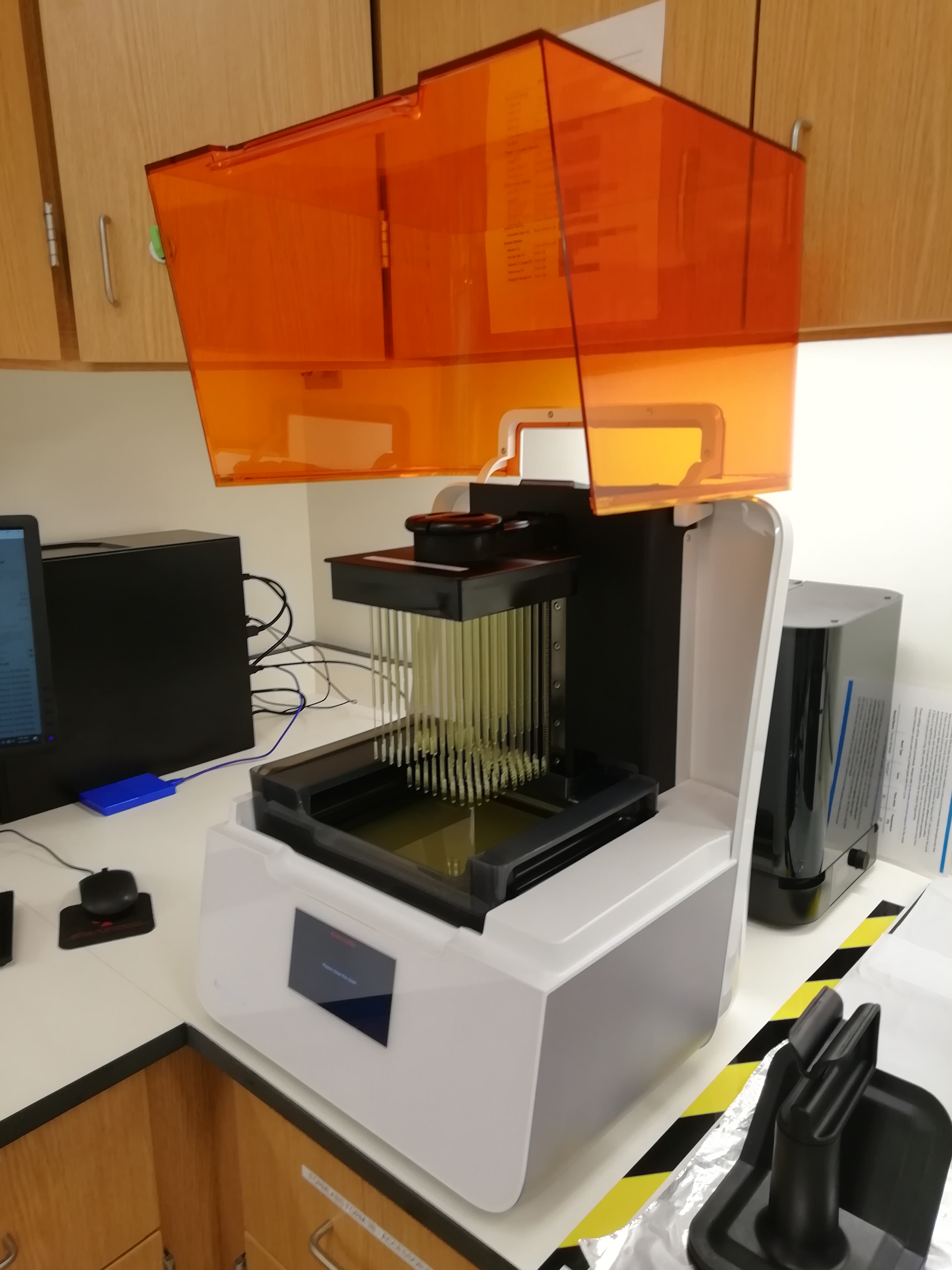

As part of the Luddy School of Informatics, Computing, and Engineering COVID-19 response, the FAMES Lab joined forces with the Protolab to determine ways in which our facilities may be of assistance. By 3D printing face shields, test swabs and respirator valves, our hope is to help alleviate the shortages of these items in the health system, enabling our health professionals to be protected and have the resources to do their best job in fighting this disease. Our prototypes are rigorously validated by IU Health and Ezkenazi Health centers to ensure their quality and suitability for clinical use before production begins. Our entire team is currently dedicated to the development and fabrication of these devices, while maintaining the highest quality and safety standards.

FAMES Lab’s face shields were developed based on designs by Columbia University, with modifications for better ergonomics, and have recently been approved for production and distribution to our health center collaborators. Thus far around 300 face shields were delivered to Brian Barrick who works at Operational Excellence and Strategy at Ezkenazi Health. 300 face shields were prepared over three weeks with a yield of 20 shields per day, working together with the Protolab. The face shields are high quality and reusable. The goal is to supply two face shields per emergency personnel at Eskenazi Health.

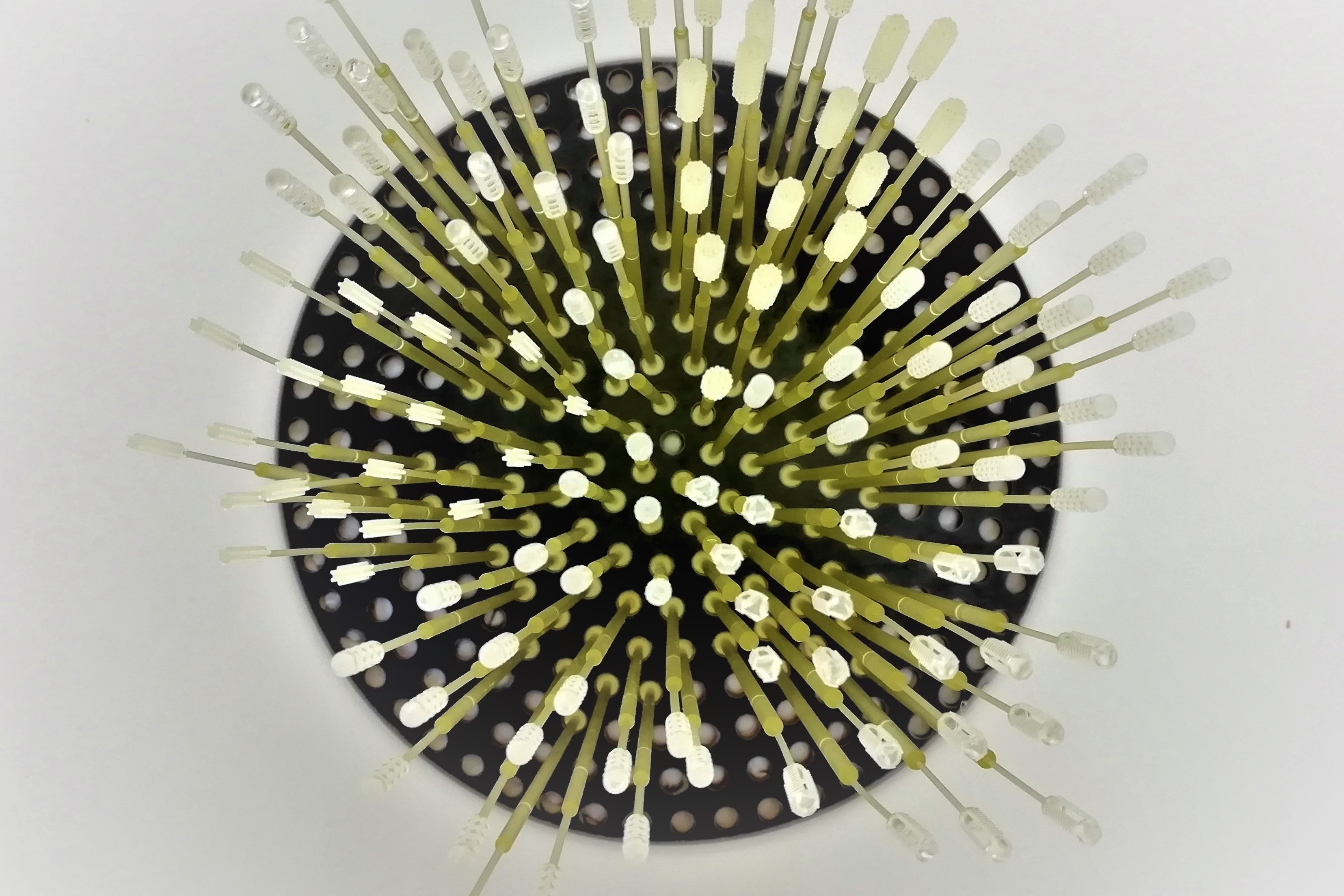

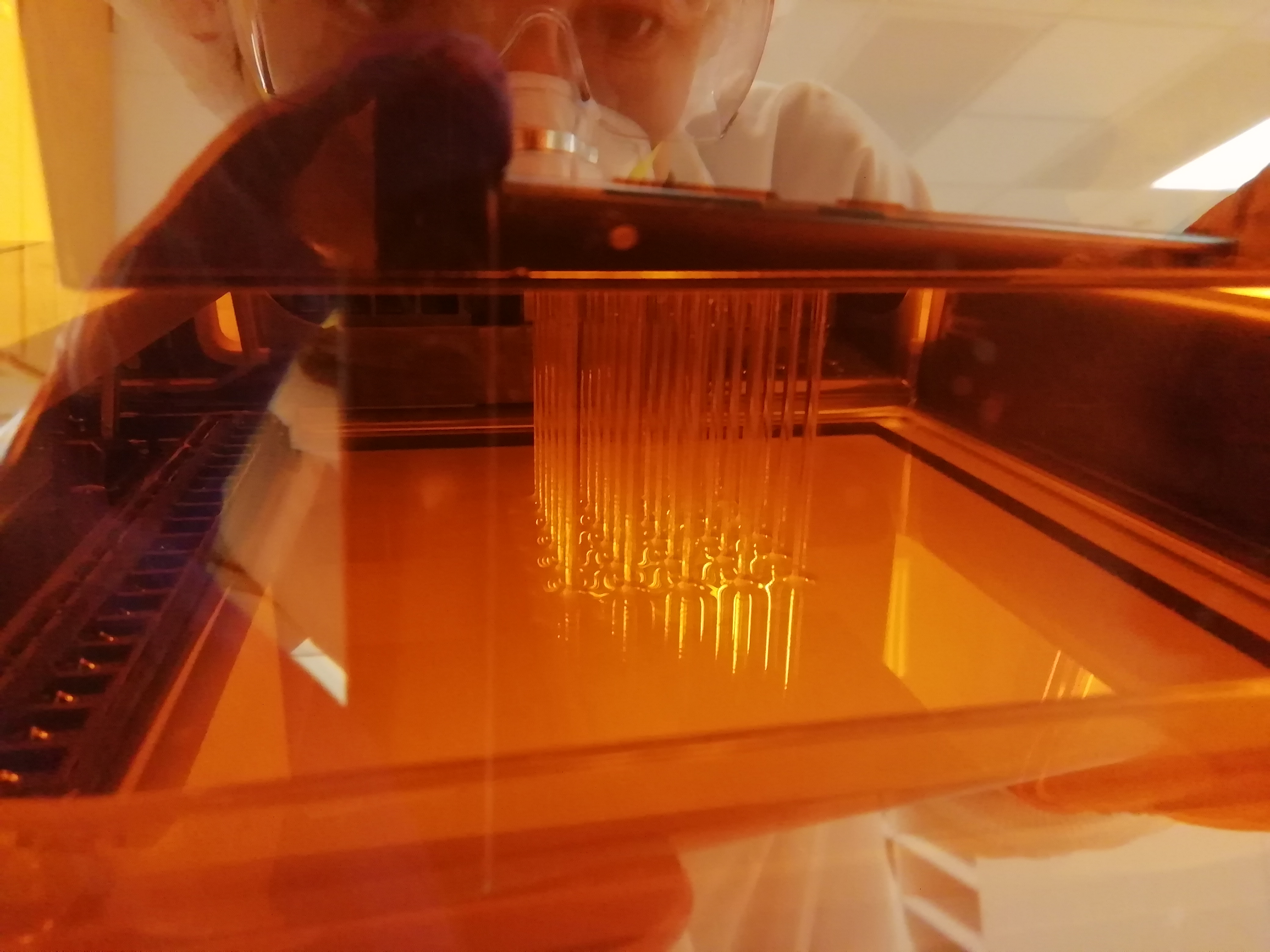

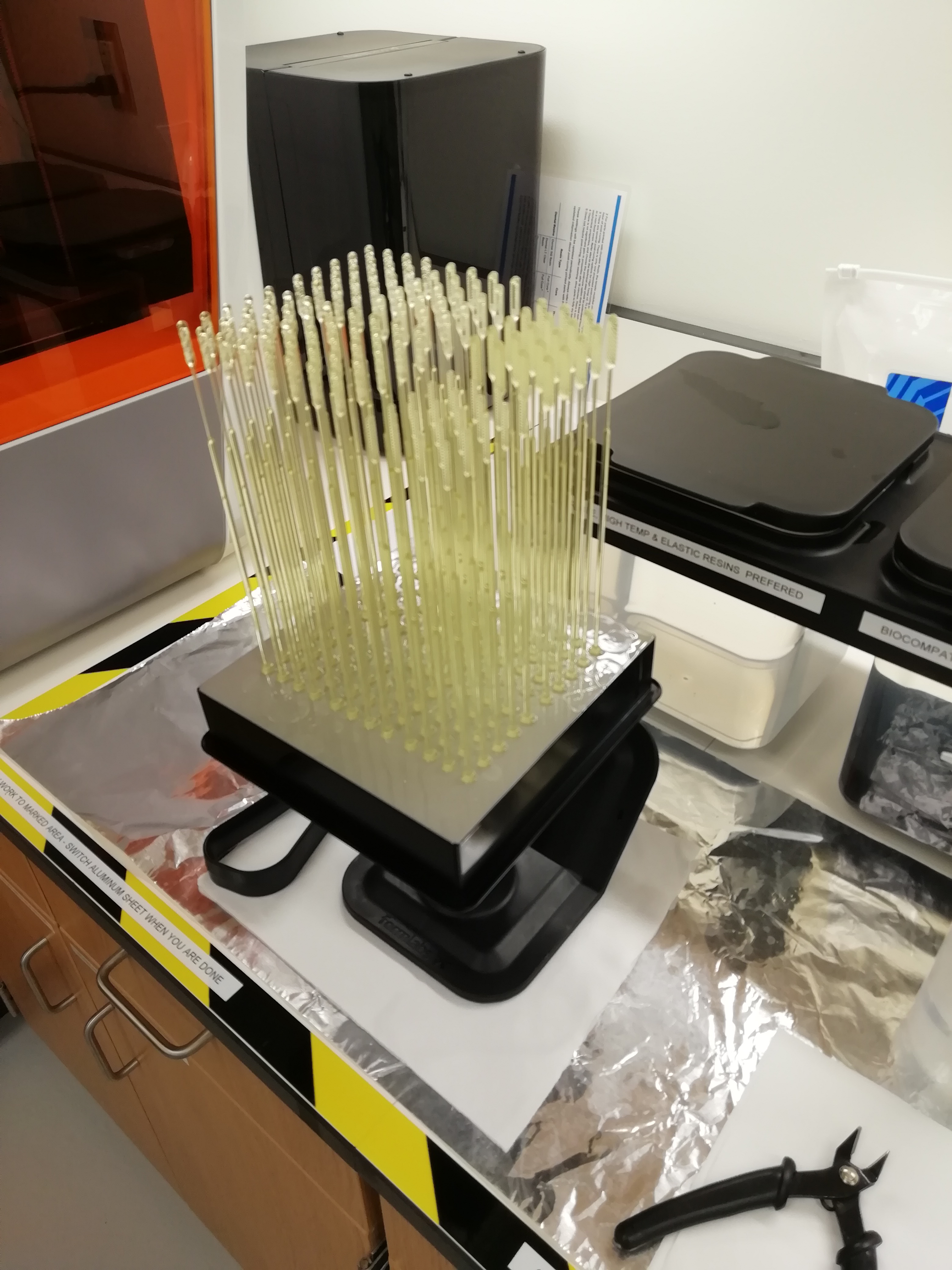

A variety of 3D printed nasopharyngeal swabs have been assessed as an alternative solution to flocked NP swabs shortages that are typically used in the healthcare industry. NP swabs are essential as they represent the first step of detection and diagnostic of the presence of the SARS-CoV-2 virus in people. The development of the NP swabs is also being done in collaboration with Deaconess Health System.

By request from the Ezkenazi Health, FAMES team has also been working on the development of Y-split valves to allow a single ventilator to be shared between two hospital patients.

Even though FAMES Lab was designed to conduct research at the forefront of science, our multidisciplinary approach to additive manufacturing enables great flexibility in our capabilities. That, alongside a team of highly qualified personnel, allows us to rise to this new challenge and contribute to the enormous efforts of the medical, scientific and industrial communities in combating this unprecedented calamity.

Work groups interested in collaborating with the FAMES Lab are welcomed to contact us. Collaborators can access open source files through our institution Box folder.

Our work is featured below in an interview by Bente Bouthier for WTIU. Further below are pictures of the FAMES Lab prototypes and products in fabrication.