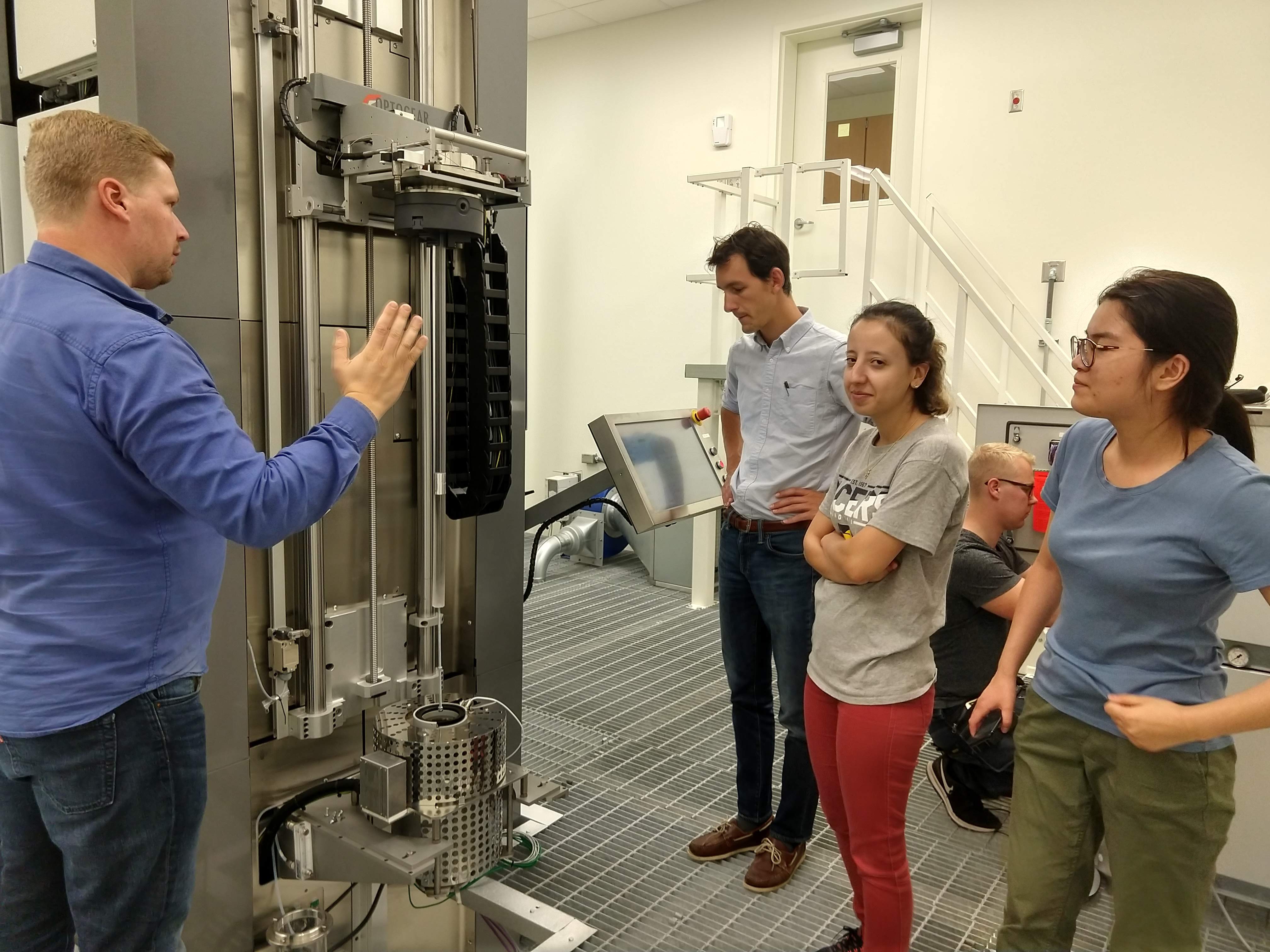

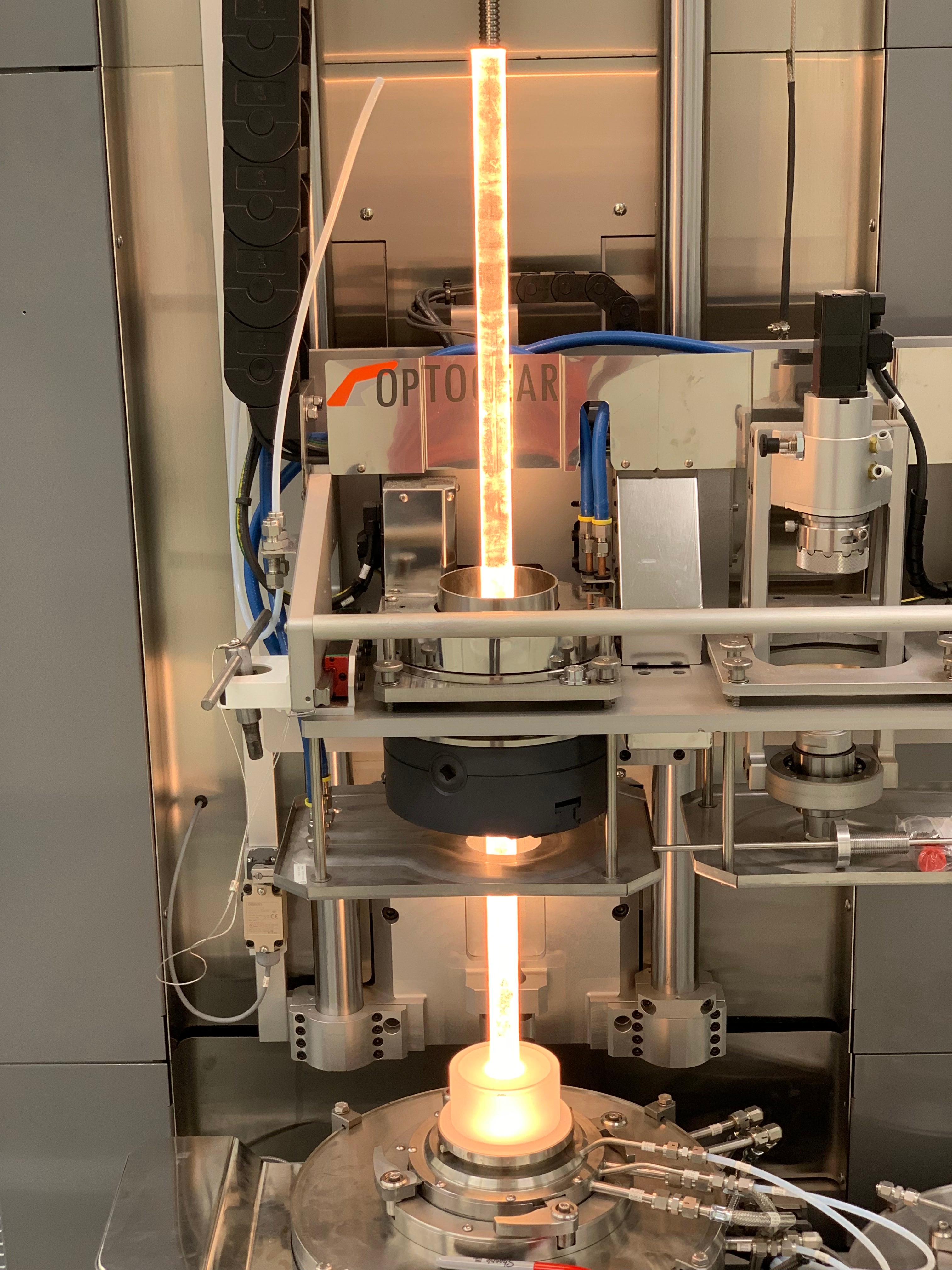

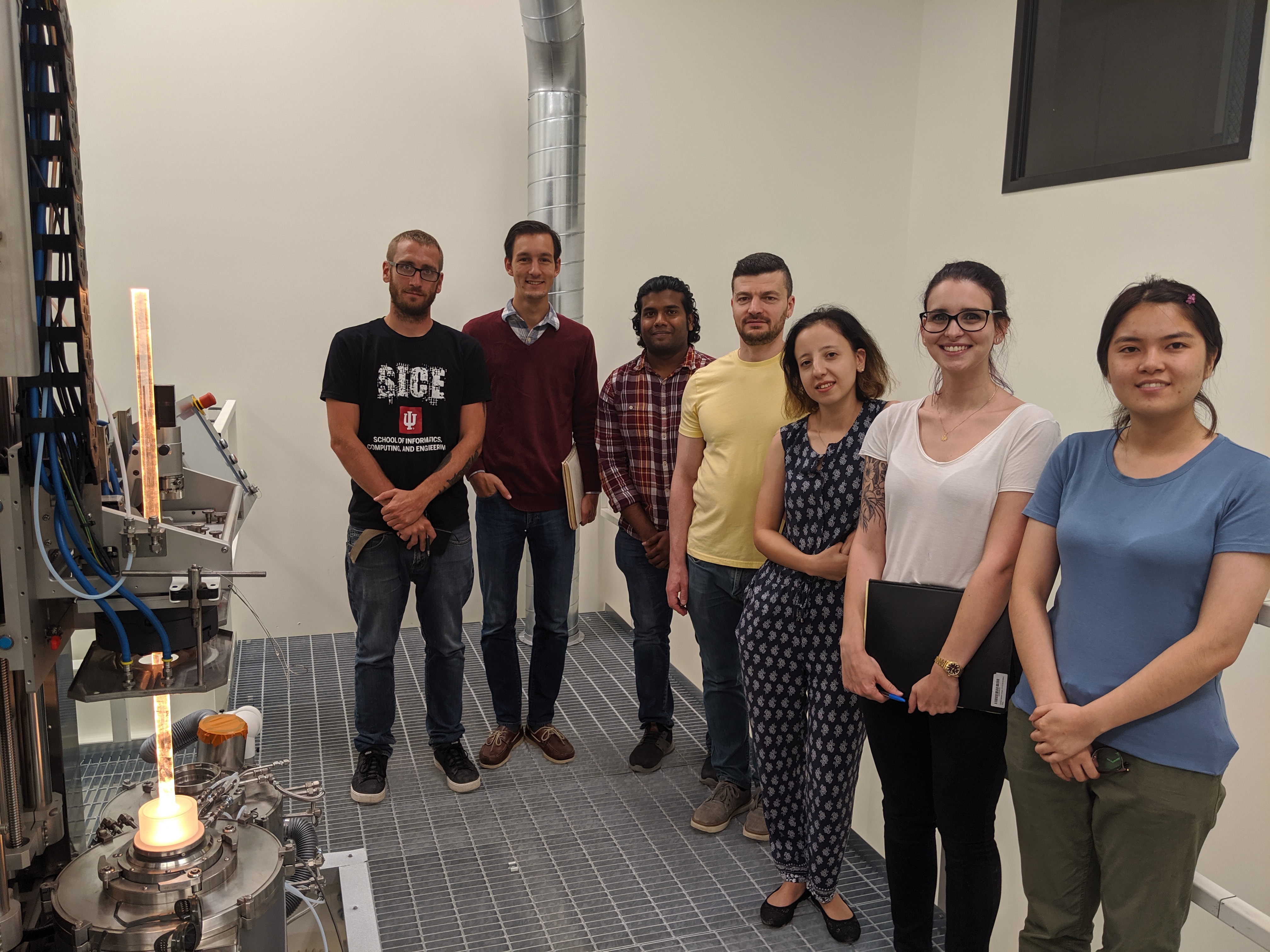

Over a week of training, the FAMES Lab team was trained to operate and maintain OptoGear’s draw tower. One side is designed for high temperature draws reaching temperatures over 2400°C typically used for glasses, and another side for low temperature ranges up to 1000°C used for polymer materials.

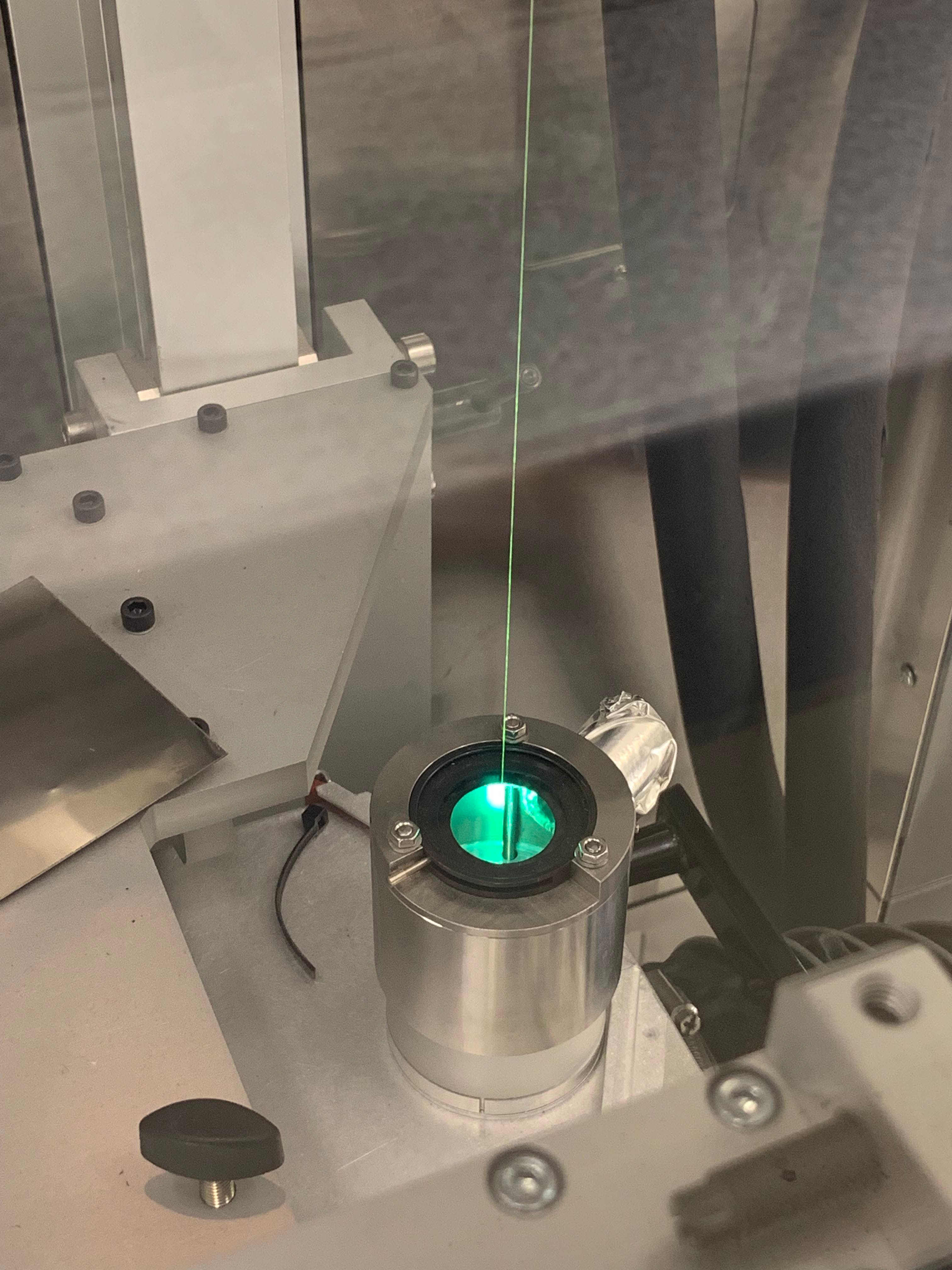

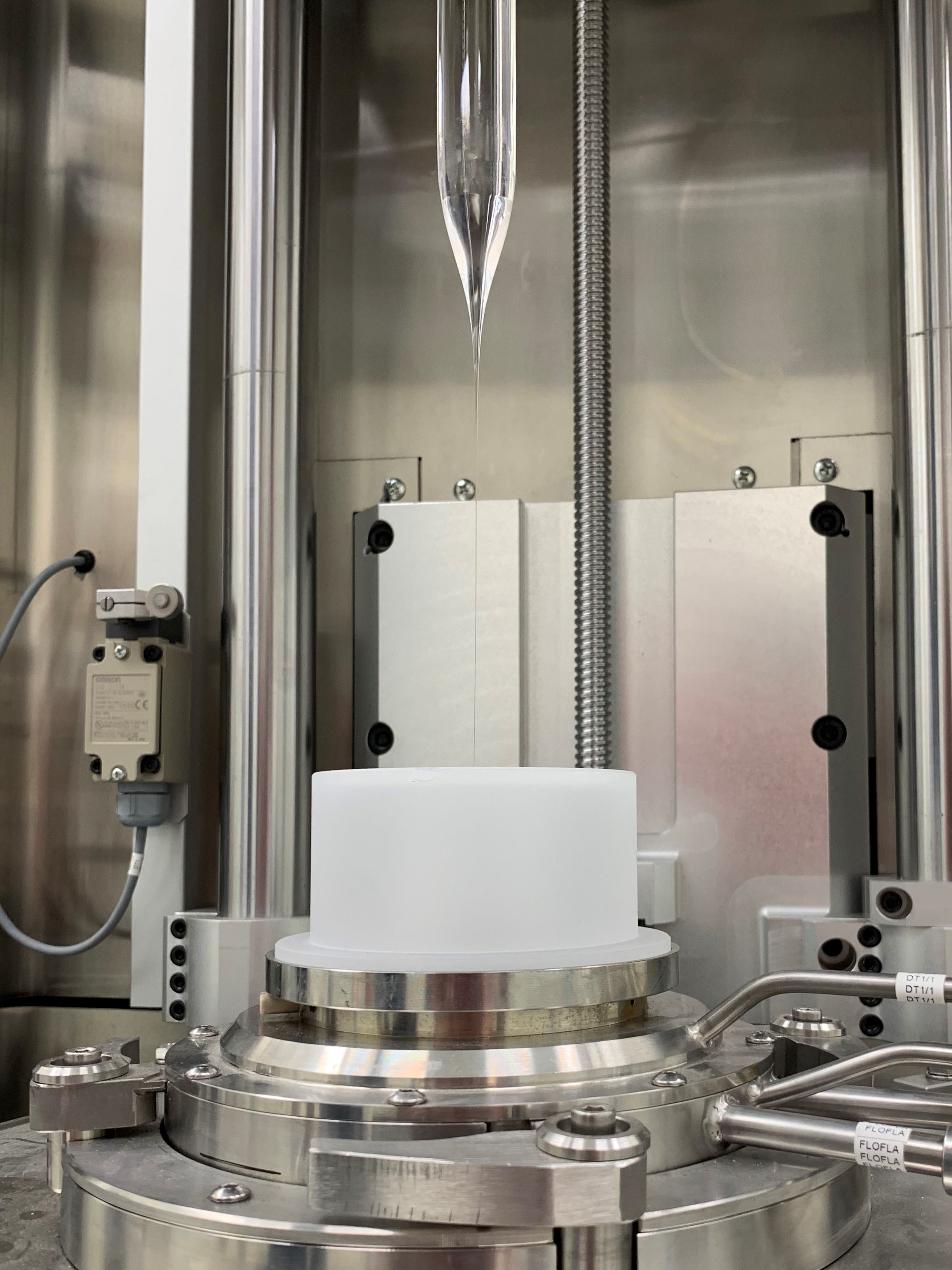

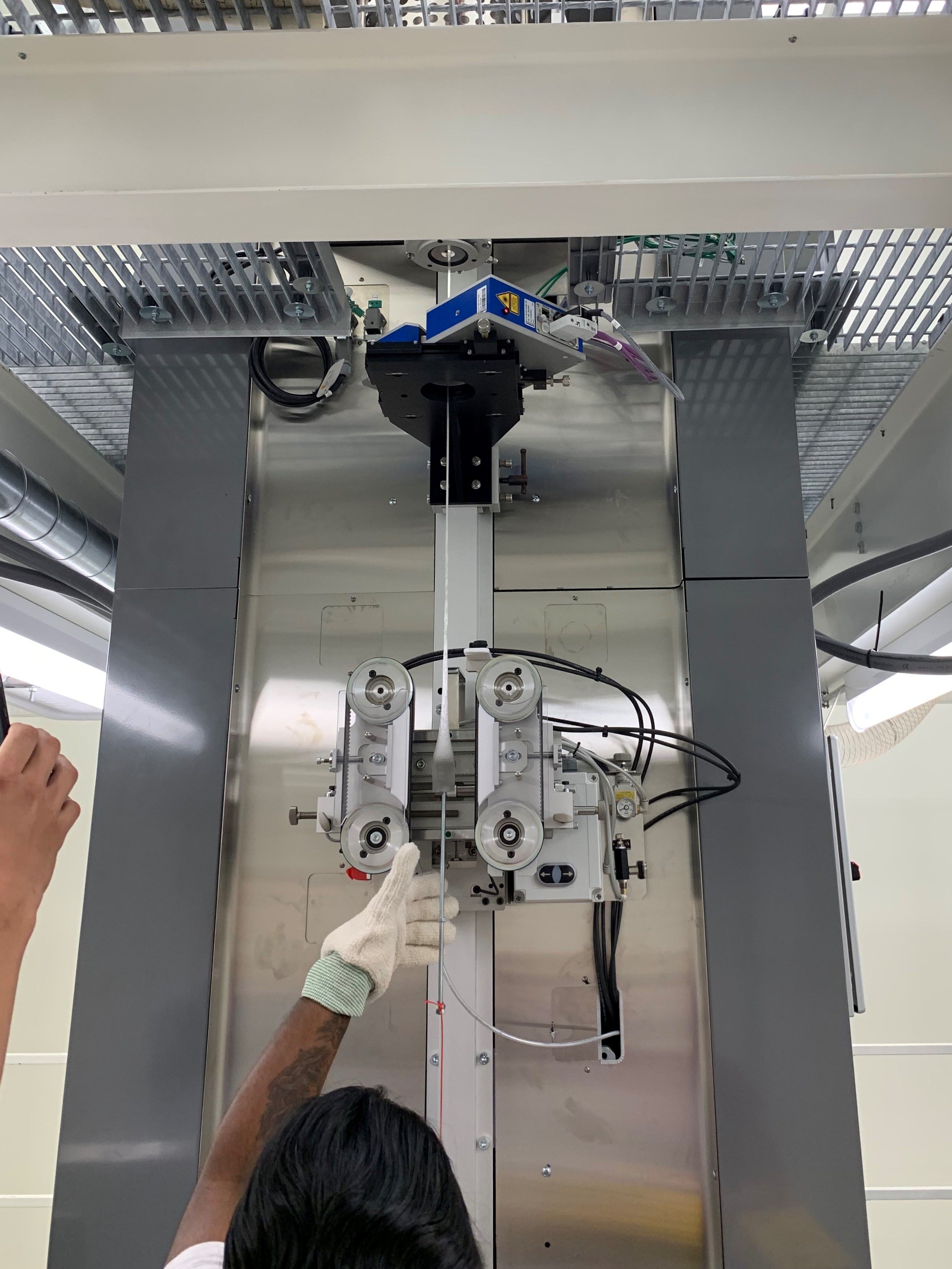

Both systems are automated with a startup capstan that helps prepare the fiber for the main capstan that will help regulate the fiber drawing conditions before it is fed into a spooling machine. The two lines are also modular. The hot temperature side includes a rotational preform feed systems up to 300RPM and a spinning preform feed system that reaches 3000RPM that enable the creation of helical structures and near-no-gravity conditions. It also includes both an induction and resistive furnace for different maximum temperatures of 2400°C, for hard glasses like borosilicate and 1200°C for soft glasses like silica, respectively. The hot temperature line has an additional UV coating system to reinforce certain properties of the drawn fiber, such as acrylate for structural flexibility. The low temperature also has a rotational preform feed system that reaches 300RPM. It includes a thermal coating setup.

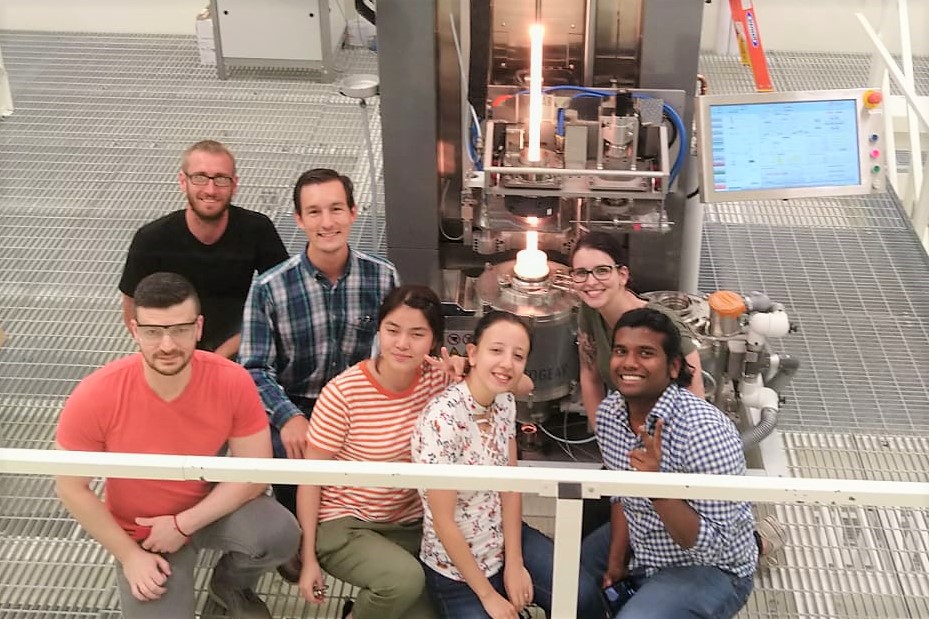

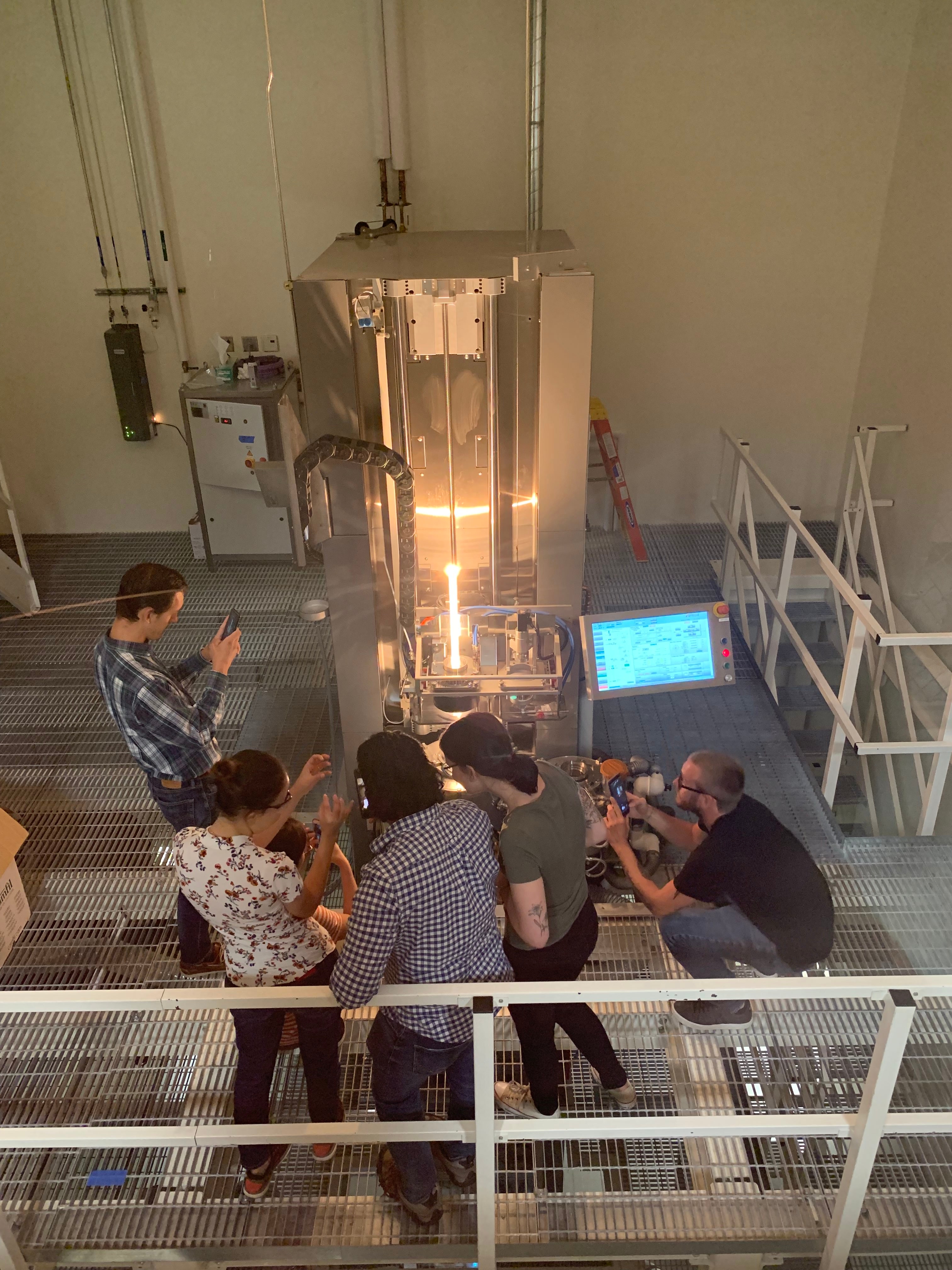

During the week of training, the team got to draw polycarbonate, silica and borosilicate, learning how to use all components of the draw tower. The two high temperature and low temperature lines can be operated independently and at the same time.