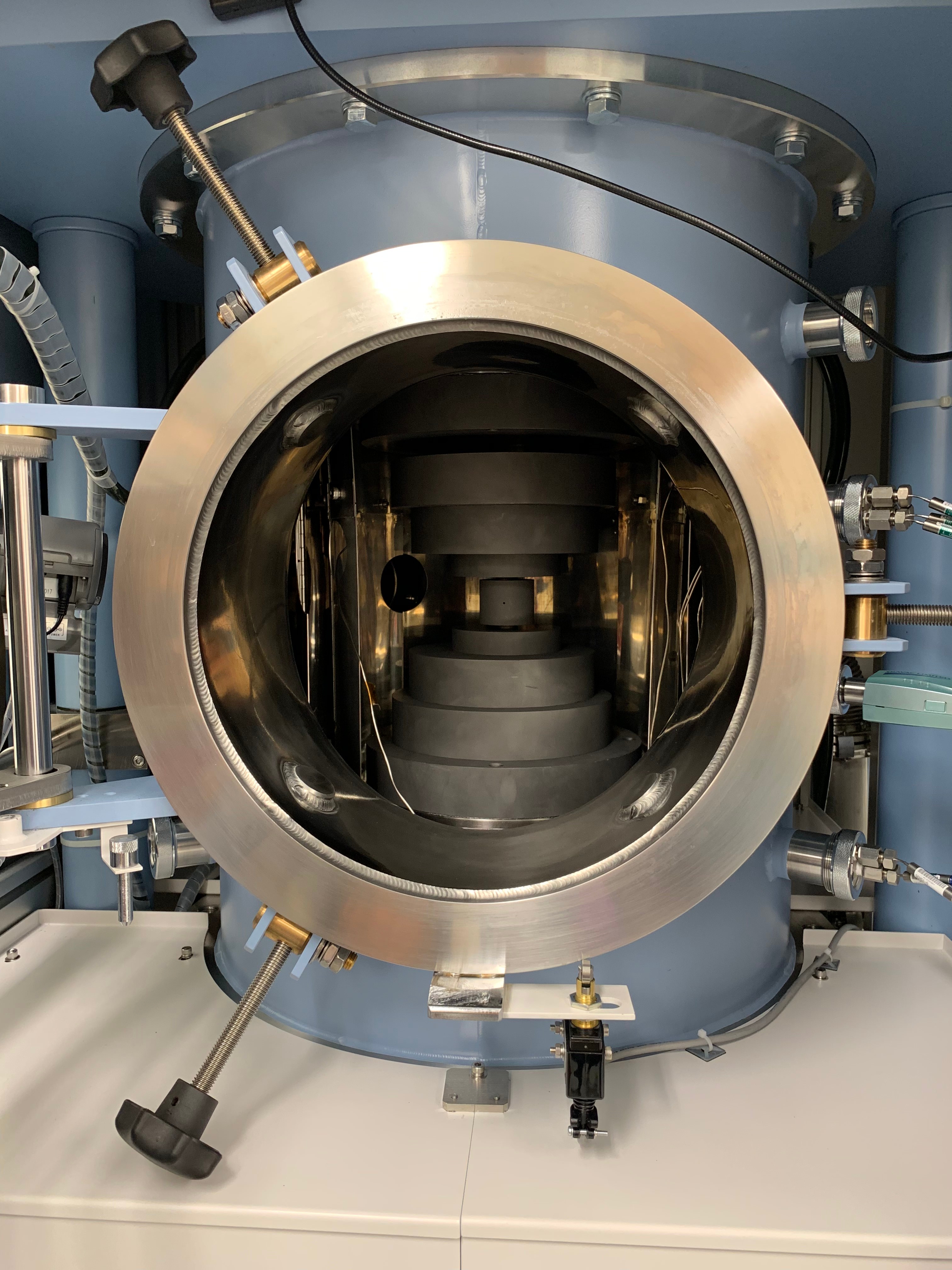

Spark Plasma Sintering (SPS), also called Field-Assisted Sintering Technique (FAST) is a sintering technique which uses, in addition to uniaxial force, a pulsed direct electrical current under low atmospheric pressure in order to consolidate a material. The SPS technique is somewhat similar to hot pressing methods, with the main difference being in the heating rates achieved, as well as in the way the heat is produced and transmitted through the material: in the SPS technique, if the sample is electrically conductive the DC current generates Joule Heating throughout the material, leading to a fast and uniform heat distribution. Among the advantages of the SPS method, the highlights include full density and controlled porosity, fast cycle times, low operating costs, ease of use, non-necessity of pre-forming and binders and the retaining of nanometric particle.

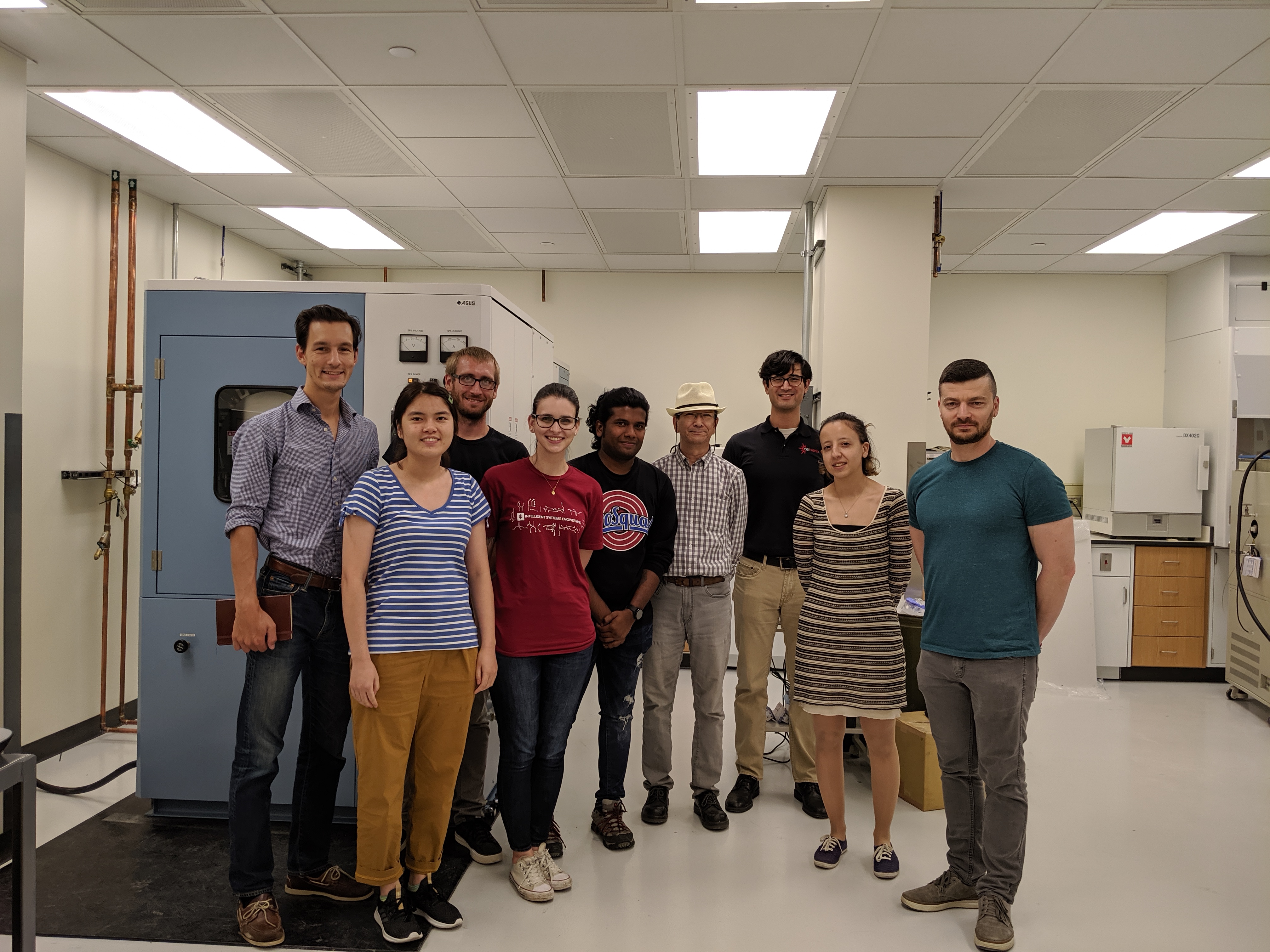

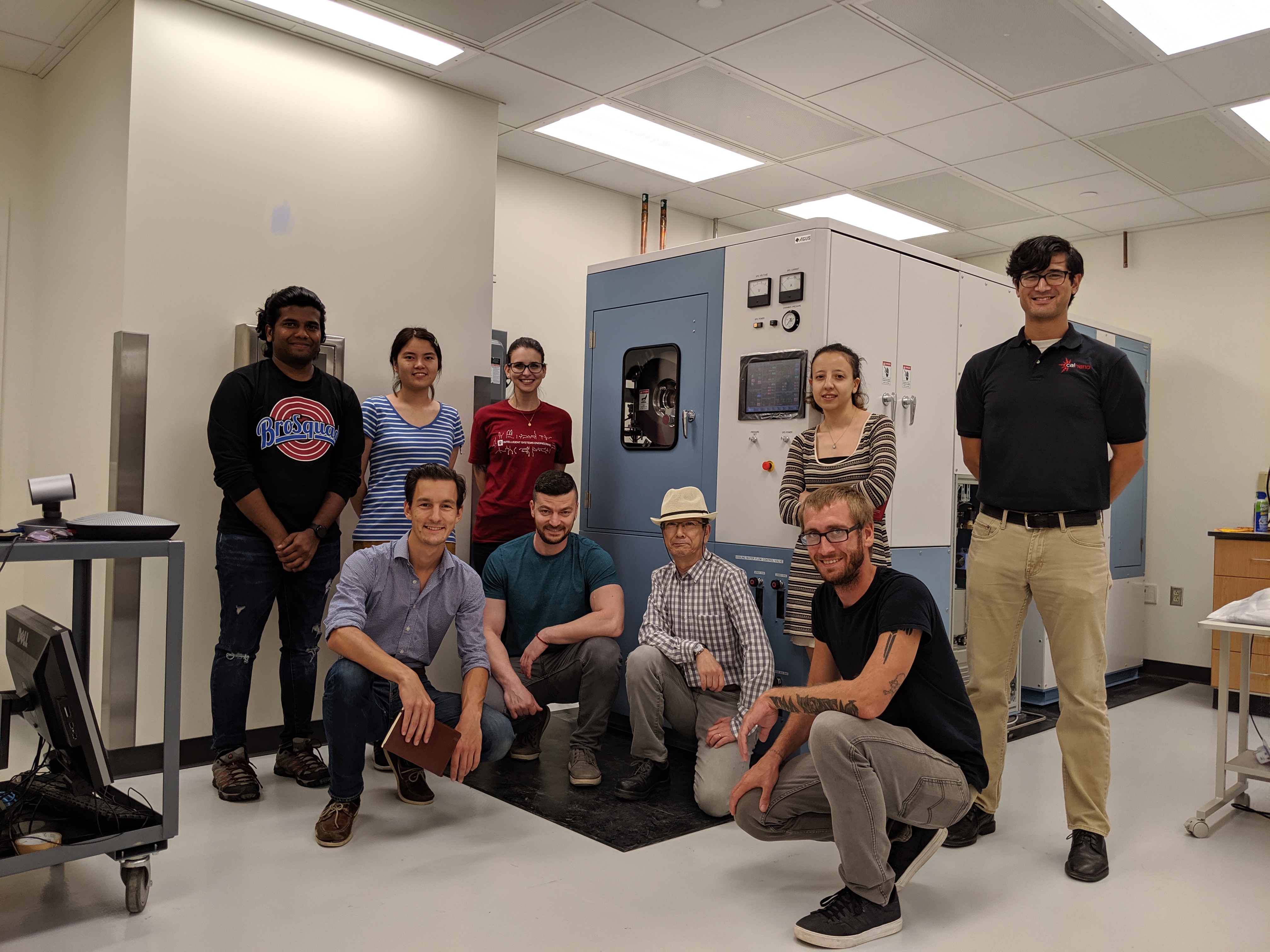

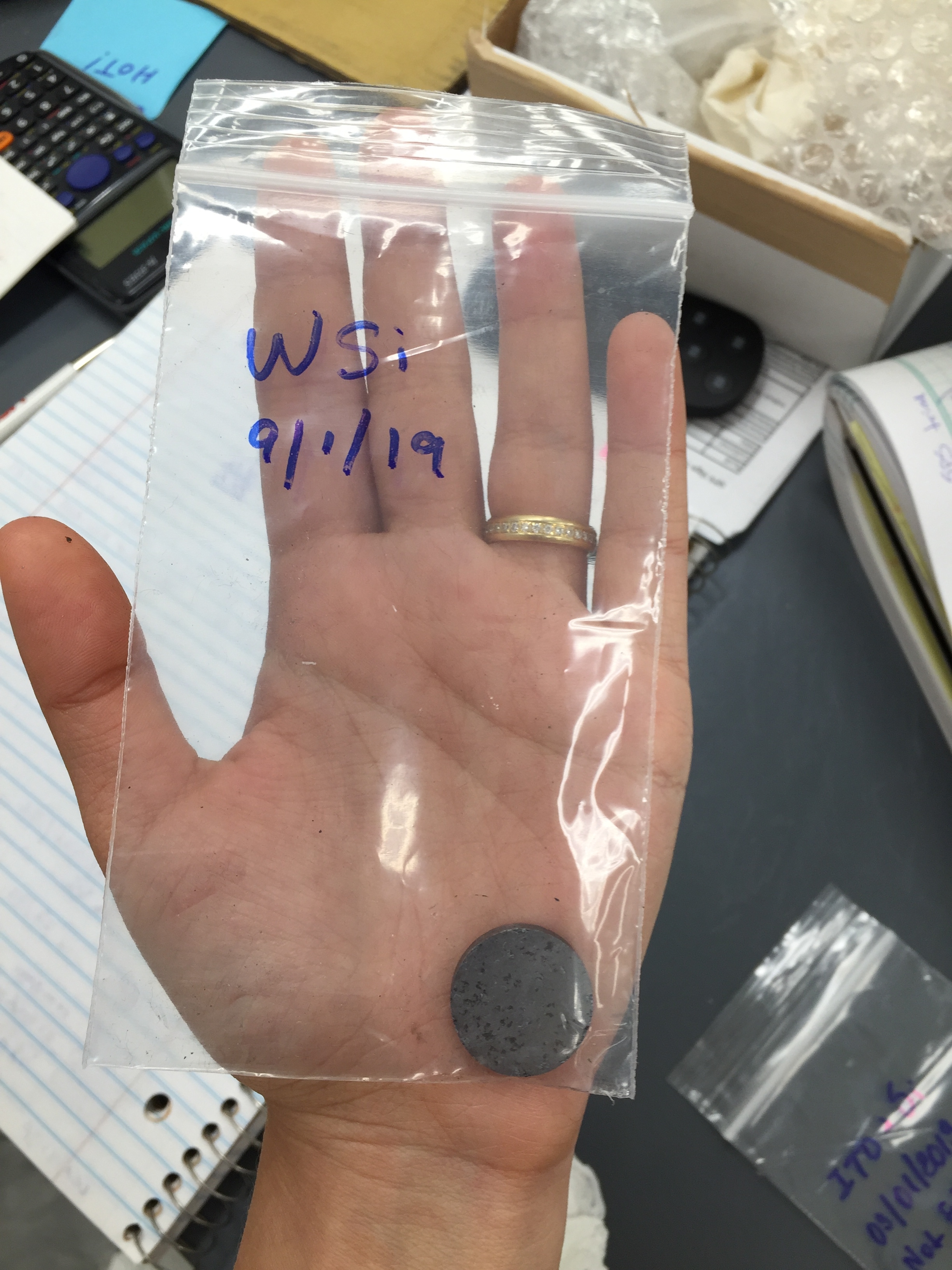

The SPS recently installed at FAMES Lab by CalNano is manufactured by SUGA Co. and reaches up to 250 kN of applied force, and is the only equipment of this kind at Indiana University. This new addition will allow FAMES Lab to process novel materials as well as increase the speed and accuracy with which traditional materials such as metals and silica can be processed. Since the microstructure of the samples can be preserved with this consolidation technique, the sintering of 3D printed parts for fiber preforms will be possible without damaging any internal structures and features.