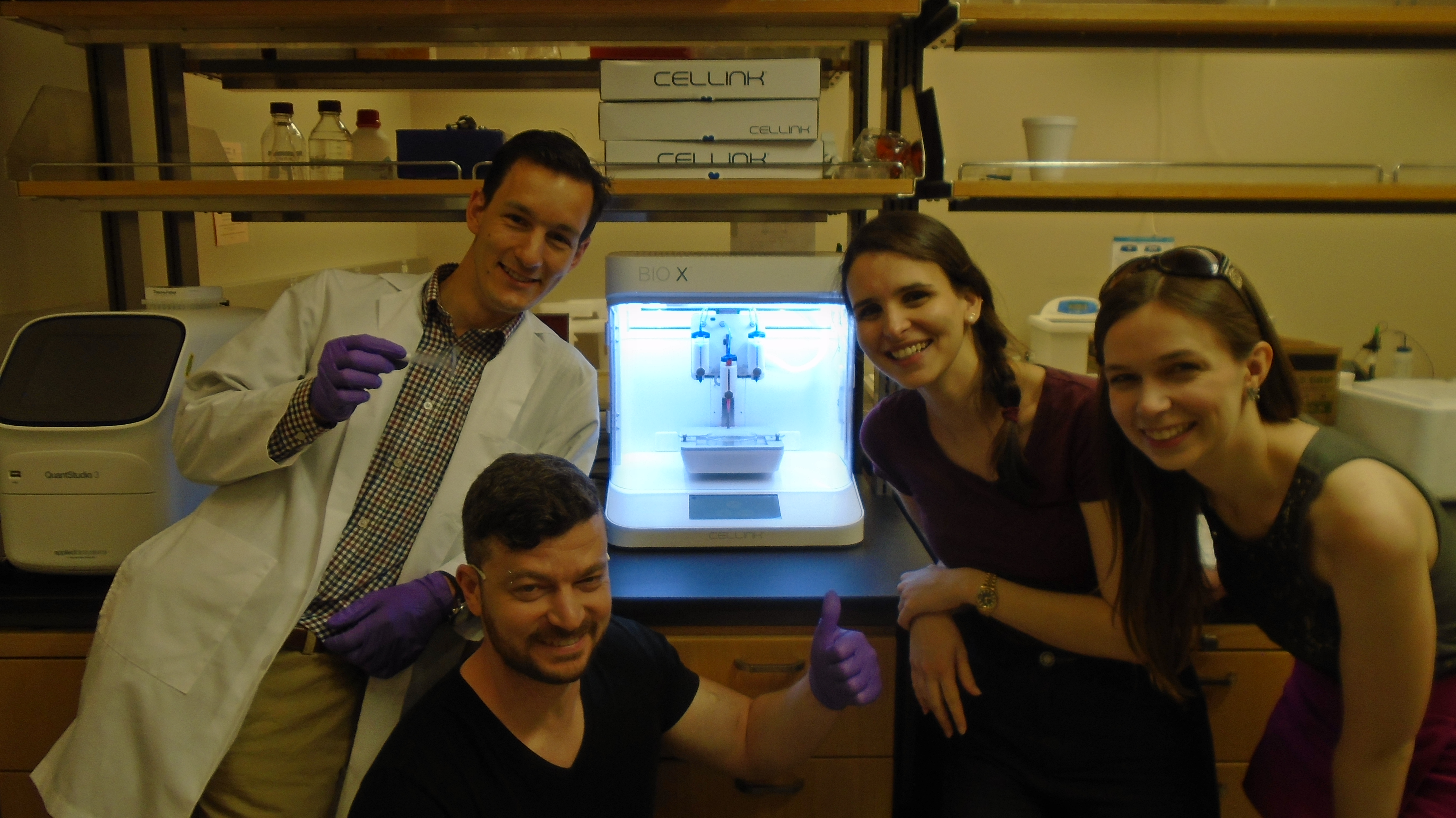

Our FAMES group is continuing to expand our approach to 3D printing capabilities and techniques with the acquisition of a bioprinter. Printing three-dimensional biological materials paves the way for innovation in several key areas, namely cell manipulation, tissue engineering, and bioprinting technology. Within such structure, our fibers holding a variety of properties such as actuation, microfluidics, or biosensing can help observe and control a three-dimensional in vitro cellular environment. The implications of such innovations are vast, including the artificial generation of tissue components for organs or other parts of the body, greater precision in monitoring cell growth, new solutions for prosthetic engineering and regenerative medicine, and more.

The bioprinting process is two-fold: our lab must first create a predefined architecture of biological materials using computer-aided design software, and then facilitate the growth of the structure such that the cells form into tissue. Our ability to successfully print biomaterial structures hinges on certain factors. Are the biomaterials printable? Will the printed materials be compatible with living tissue? Will our structures properly imitate the structural and mechanical properties of biological systems?

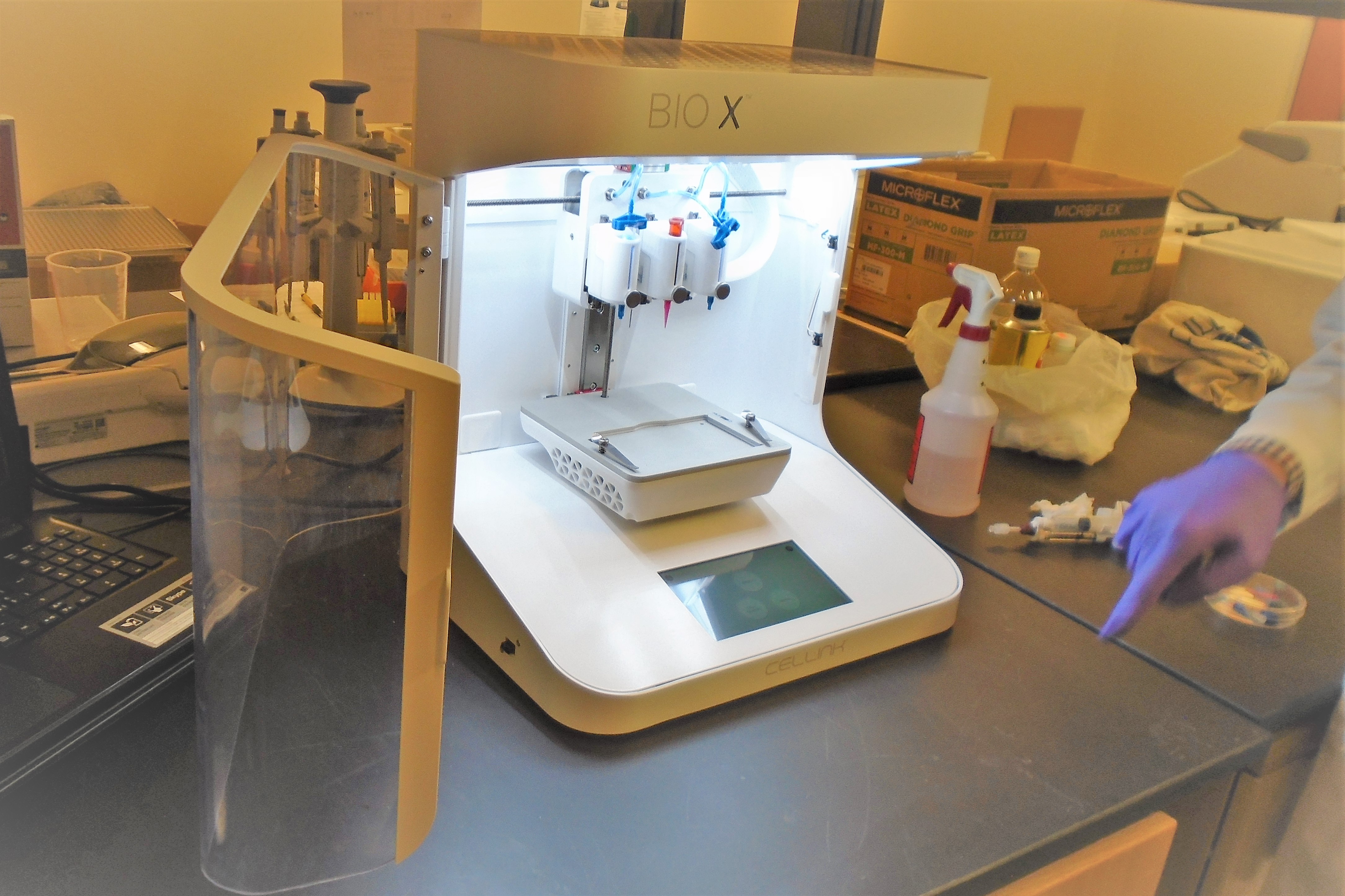

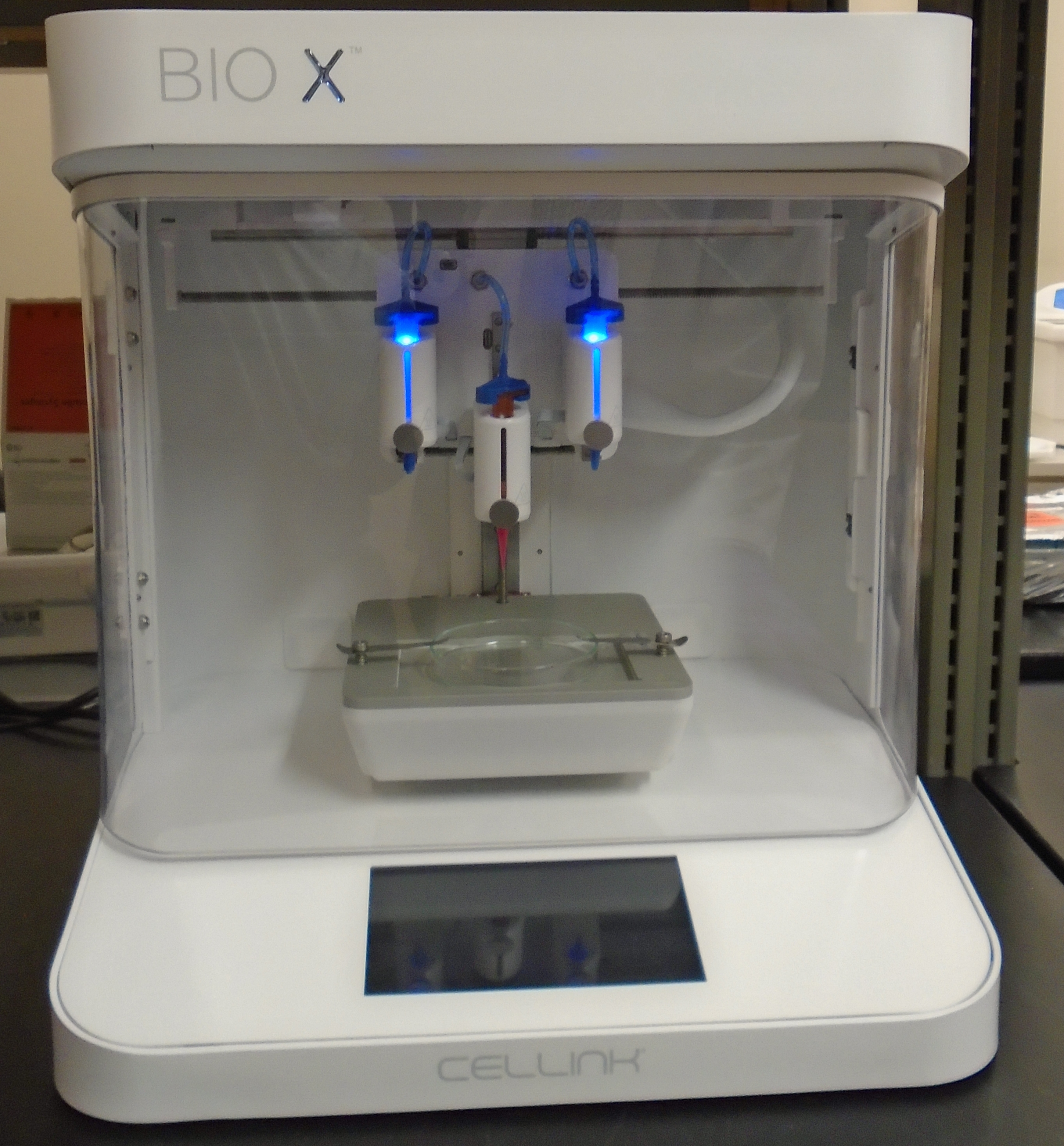

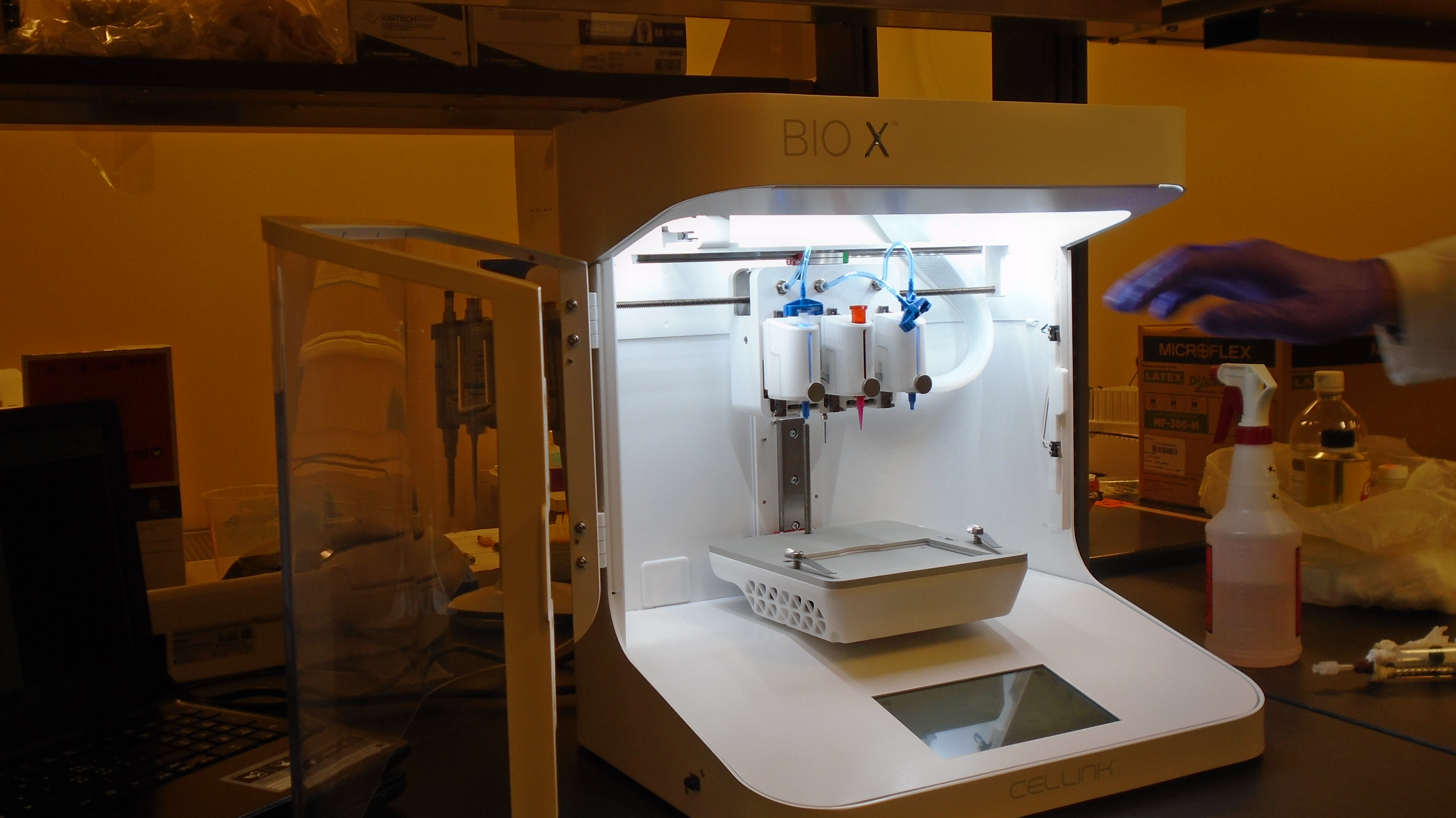

Our new CELLINK BIO X 3D bioprinter is a flexible, innovative, and user-friendly tool that is allowing us to challenge these factors. Through an extremely precise deposition of desired bioink, the printer facilitates the remaining process of tissue generation, wherein the cells are left to naturally grow and develop their own system. In essence, our work with this printer will help our team advance the influence manmade technology will have on the artificial generation of tissue components.